RFID Applications

RFID software from Turck Vilant Systems comprises 30+ ready applications that we can configure to serve a given customer use case.

Powering Intelligent Data Capture

By capturing data at key points, our customers gain insights into their processes and actionable information on their inventory levels and shipment accuracy. We have finetuned our applications in close collaboration with our customers to serve most industrial use cases.

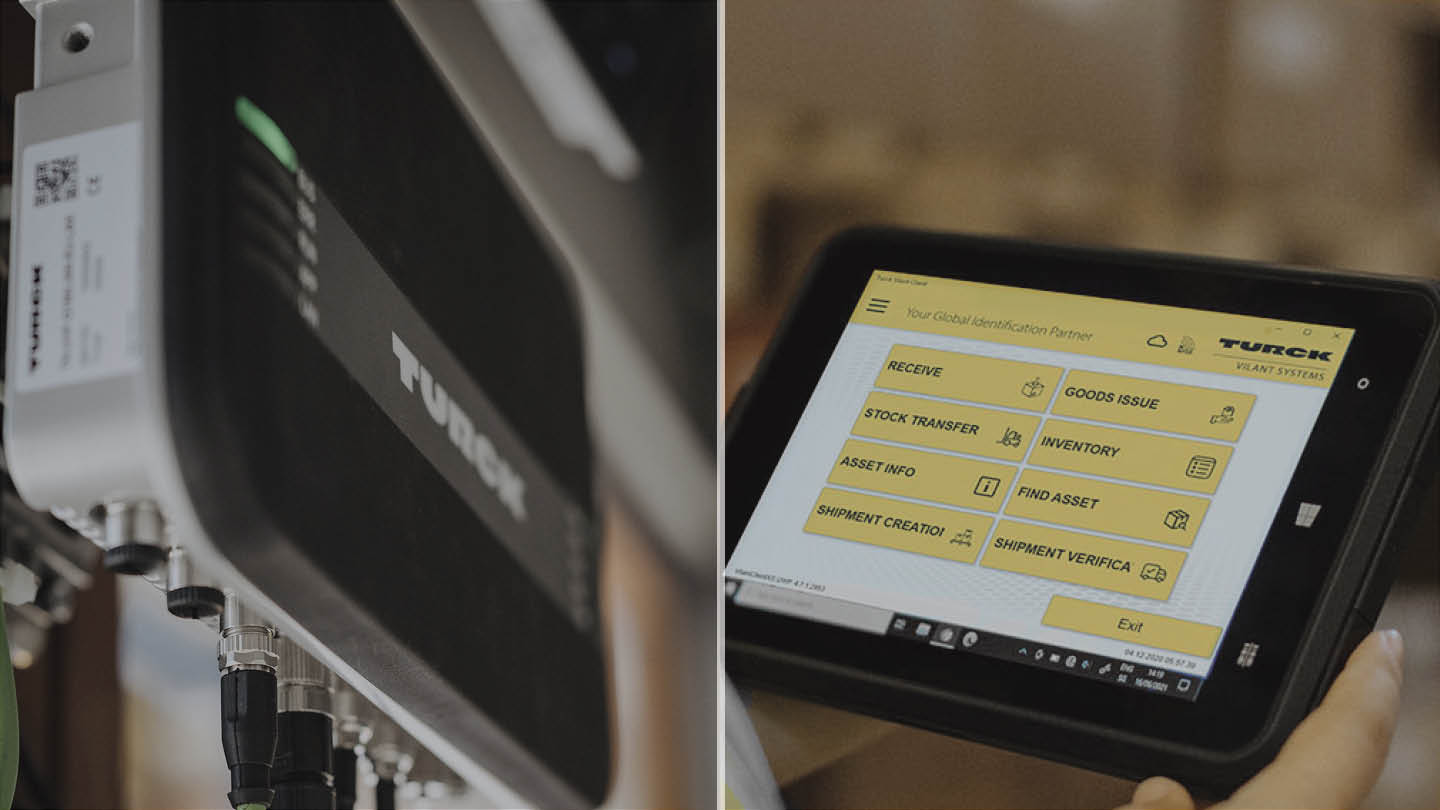

Our RFID software kit comprises 30+ applications that run autonomously on RFID readers or, when operated by the user, on Windows and Android environments.

Essential RTLS & RFID Software Features

When considering RFID or RTLS solutions, we advise our customers to ask themselves where and what the gap in their data is. Typically, ERP and WMS systems lack visibility to operators on the shop floor, and tracking platforms fill this gap by collecting data on operators’ actions, guiding the operators and finally feeding data back to business systems.

The Turck Vilant Track-and-Trace platform comprises of middleware, data collection applications installed on different RFID read points and RTLS locators. At the heart of data collection are our Turck Vilant Client and Turck Vilant Node / Turck Vilant Engine applications.

Key Use Cases in our Applications

- Stock Transfer / Item Move / Location Updates

- Shipment or Loading Verification

- Inbound / Outbound Delivery Registrations with Direction Detection

- Picking

- Search

- Inventory / Cycle Count / Partial Inventory

- Label Generation / Asset Activation / Printing

Our Data Collection Applications

Our RFID software kit features over 30 applications designed for versatile deployment. The Data Collection software offers two versions: a Node/Engine that runs autonomously on 10 different fixed RFID reader models, and a Client version with a user interface, compatible with Windows and Android PCs, industrial tablet PCs, industrial forklift PCs, and 21 different handheld devices, including phones and mobile RFID readers.

Engine / Node

The Turck Vilant Node and Turck Vilant Engine have 20+ ready applications that we can configure to serve a given customer use case.

This application runs autonomously on selected RFID readers and supports the use on

- Gates

- Tunnels

- Conveyor Lines

- Forklifts, Payloaders and Tractors

Client

The Turck Vilant Client has 20+ ready applications that we can configure to serve a given customer use case. This application runs on Windows and Android platforms and supports the use on

- Forklifts, Payloaders and tractors

- Gates

- Handheld devices inlc. phones with RFID accessories

- Self-service stores and Storage rooms

Engine / Node

The Turck Vilant Node and Turck Vilant Engine have 20+ ready applications that we can configure to serve a given customer use case.

This application runs autonomously on selected RFID readers and supports the use on

- Gates

- Tunnels

- Conveyor Lines

- Forklifts, Payloaders and Tractors

Client

The Turck Vilant Client has 20+ ready applications that we can configure to serve a given customer use case. This application runs on Windows and Android platforms and supports the use on

- Forklifts, Payloaders and tractors

- Gates

- Handheld devices inlc. phones with RFID accessories

- Self-service stores and Storage rooms

Turck Vilant RFID Applications for Data Collection

Supports over 30 different readers

Smart Algorithms enable advanced features like direction detection and forklift operation

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.

Read More

middleware

Consolidating Data for Actions

Track & Trace Middleware from Turck Vilant Systems collects data from and remote manages RFID devices and printers.

rfid gate

Automated Entry and Exit Points

With automatic direction detection for inbound and outbound goods, our RFID Gate keeps stock data updated

Forklift rfid

Warehouse Transactions Tracked

An intelligent track-and-trace application knows what a forklift carries on its fork and tracks the location automatically.

mobile devices

RFID System in Operator's Pocket

Mobile RFID applications extend the technology everywhere. Users carry data on stock levels and quality with them at all times.

Look for at least these features in your RTLS and RFID Applications

1. Data Capture: The software should identify and capture data from selected tags accurately and efficiently.

2. Support for mix-and-match environment: Industrial companies seeking better operational visibility need a mixture of identification points throughout their production and warehouse and between different sites. When looking for a system, opt for one that has applications optimized for different processes including forklift use; installations on dock doors, conveyor lines, production lines, and supporting self-service

3. Real-time inventory data: Given that most traceability projects stem from lack of visibility to material, asset or product visibility, the chosen solution should include real-time updates to needed inventory data.

4. Supported use cases: What is it that you need to do? Do you hope to identify items on a paint line, replenish shelves as materials are used, ensure correct items are shipped or manage which parts are added to a ready product on a production line? What ever the need is, make sure the software application supports that particular use case, either the way it is now, or with the help of customization.

5. Scalability: How well does the system work in case you have tens of identification points, or hundreds? The platform should scale up to support hundreds of identification points and still run smoothly.

6. Customization: Can the application be customized in case something does not fit your process? It would be advisable to ensure a level of customization is available, though one should always carefully consider how much customization should be added, to secure also future updates and their ease.