RFID & RTLS for Traceable Handling and Faster Warehouse Operations

RFID & RTLS cut search time, automate picking, and speed up shipment processing by up to 87%—thanks to their ability to operate at speeds up to 100 times faster than barcodes.

A short introduction to Warehouse Inventory and Location Tracking

RFID ensures fast and error-free warehouse inventory tracking by automatically registering material arrivals, locations, and movements – enabling real-time visibility and accurate stock levels.

The Turck Vilant Systems Warehouse Inventory and Location Tracking Solution

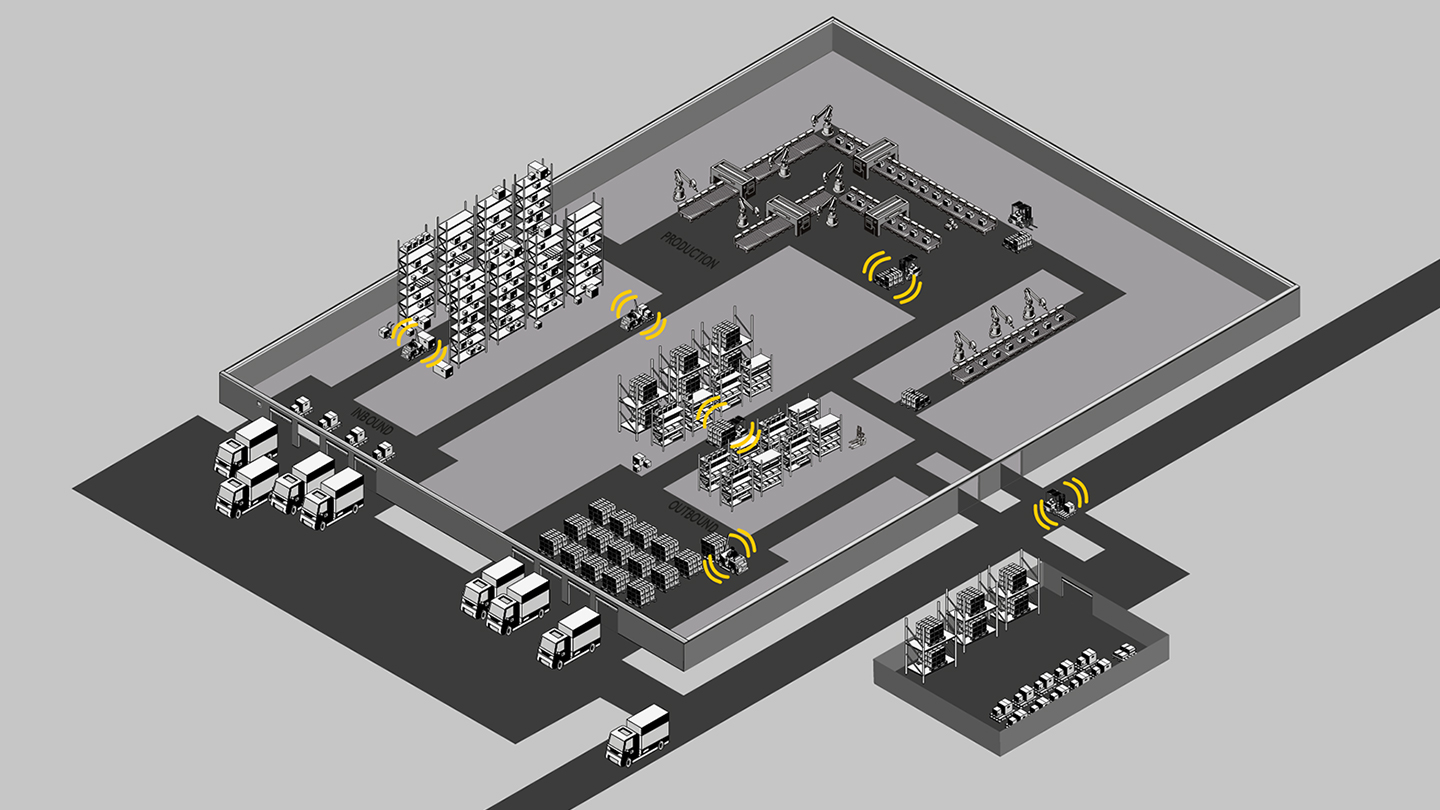

Keeping track of materials and inventory is essential for production planning and order fulfillment. RFID enables identification and tracking at speeds up to 100 times faster than barcodes, while also allowing automation of the entire process. Depending on your needs, technologies like RTLS offer even higher precision—down to shelf or item level—allowing us to tailor the solution to the required level of accuracy.

Turck Vilant Systems provides a Track and Trace toolkit that assigns a unique identity to each product or batch. From that point forward, the item or lot is tracked automatically whenever it passes a read point—on a conveyor, forklift, or at warehouse entry / exit. This speeds up shelving, picking, locating, loading, and overall tracking while also ensuring inventory and shipment accuracy, meeting traceability requirements, and eliminating manual errors through automation.

Turck Vilant Systems Warehouse Inventory and Location Tracking Solution

- Assigns a unique identifier to inbound materials, whether at the source or upon arrival at the warehouse.

- Automatically registers inbound materials and inventory as arrived

- Records the stock location of products or batches

- Tracks all warehouse transfers made with forklifts

- Ensures delivery accuracy by verifying correct products are loaded

- Logs all RFID events and documents the history of each individual batch o materials.

How to implement RFID and RTLS for a warehouse

Placing RFID read points at key warehouse zones and transition points enables real-time visibility into material availability. When integrated with forklift operations, stock movements and location updates are logged automatically—eliminating manual input and delays.

Material Inbound

Material is received from suppliers through RFID gates that automatically receive the goods to backend system.

Shelving

Material enters the inbound warehouse via RFID gates or RFID forklifts. Stock transfers are automatically updated in the WMS, with shelf-level accuracy when using forklift-based RFID.

Picking

Forklifts equipped with RFID can be used to pick items for production ramp-up. The system pinpoints the correct stock location for the forklift operator.

Consumption

The Track & Trace system enables full material traceability, automatically booking consumption and linking it to the right project, order, or product.

Finished Product

At the end of production each product, batch or pallet is RFID tagged.

Stock / Warehouse

Forklifts and payloaders equipped with RFID automatically register the stock location of the final product, batch or pallet.

Picking

Forklifts equipped with RFID are used to pick items against a customer order for shipment to ensure picking accuracy.

Loading

As products are loaded the RFID application verifies the shipment data against the customer order and ensures nothing is left behind.

Receiving

Material is received from suppliers through RFID gates that automatically receive the goods to backend system.

Shelving

Material enters the inbound warehouse via RFID gates or RFID forklifts. Stock transfers are automatically updated in the WMS, with shelf-level accuracy when using forklift-based RFID.

Picking

Forklifts equipped with RFID can be used to pick items for production ramp-up. The system pinpoints the correct stock location for the forklift operator.

Consumption

The Track & Trace system enables full material traceability, automatically booking consumption and linking it to the right project, order, or product.

Finished Product

At the end of production each product, batch or pallet is RFID tagged.

Warehouse

Forklifts and payloaders equipped with RFID automatically register the stock location of the final product, batch or pallet.

Picking

Forklifts equipped with RFID are used to pick items against a customer order for shipment to ensure picking accuracy.

Loading

As products are loaded the RFID application verifies the shipment data against the customer order and ensures nothing is left behind.

Solution benefits

Stock levels always up-to-date

Picking and delivery accuracy through automation

Easy backwards traceability of production batches

Up-to-date stock location information

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.