RFID Packaging Testing: How Smart Sorting Drives Recyclable Plastics in Europe

Plastic pollution is no longer a distant threat — it’s in our oceans, in our food, and even in our bodies. By 2060, global plastic waste is set to nearly triple unless decisive action is taken. To drive change, a leading plastics sorting facility uses RFID technology to help brand owners redesign packaging that sorts — and recycles — better.

Why Plastic Recycling Matters

World Economic Forum’s Global Risks Report 2025 ranks pollution among the 10 risks with the most severe expected impact over the next decade. Plastic pollution is a main culprit.

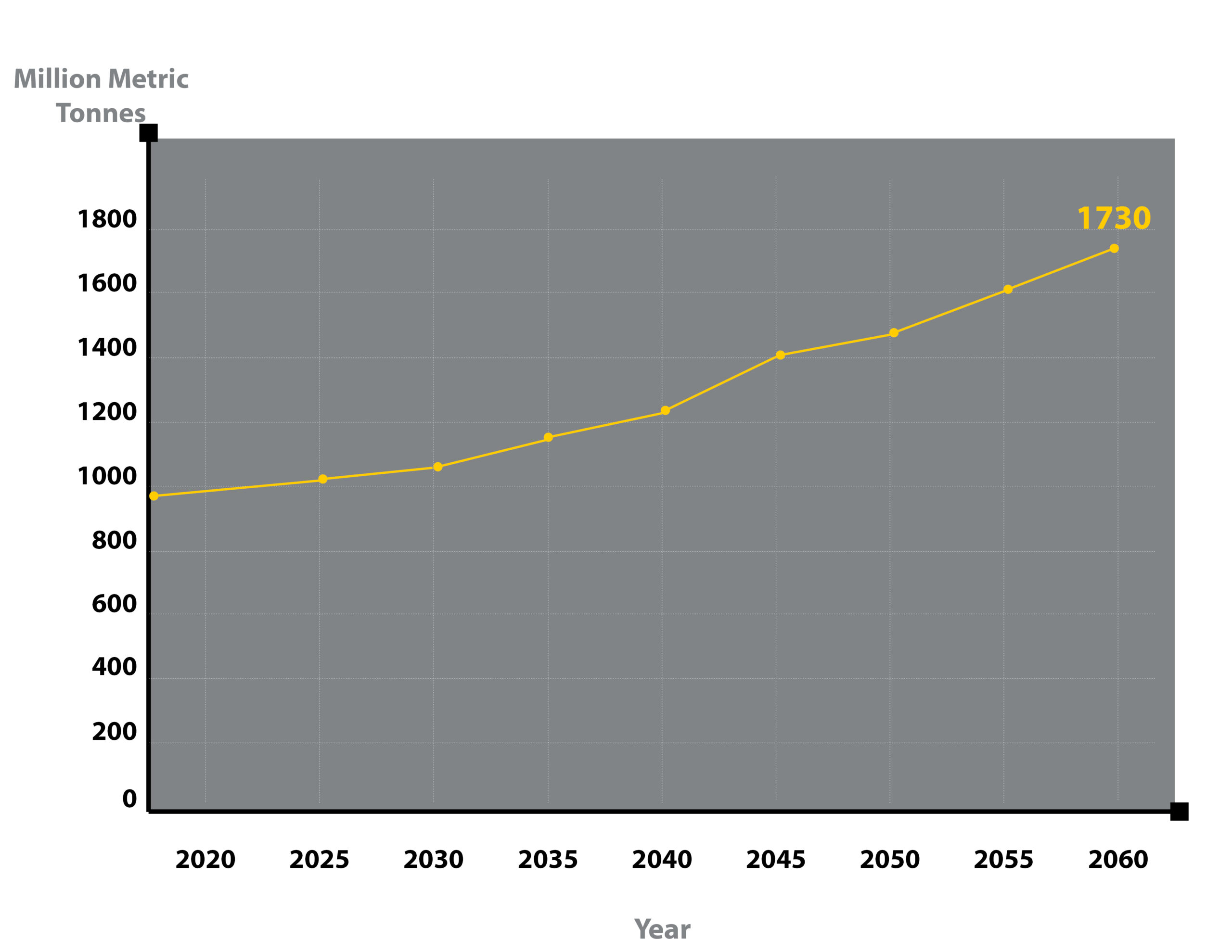

The scale of this challenge is evident: OECD data shows that plastic waste is growing far faster than our ability to recycle it.

Stricter policies are emerging, but they won’t be enough — the key is how technology and innovation can enable truly recyclable packaging and boost plastics’ second life.

Global Plastic Waste: Key Facts

- During 2025, global plastic waste will exceed 1 billion tonnes.

- Without stronger action, this could rise to 1.7 billion tonnes by 2060.

- Under current policies, plastic waste will almost triple by 2060.

- Less than 20% is recycled — the rest is landfilled, incinerated, or leaks into the environment.

- Most of the waste comes from single-use plastics: bottles, caps, bags, disposable cups and straws.

Global plastic waste projections 2020–2060. (Source: Organisation for Economic Co-operation and Development, OECD)

RFID Packaging Testing in Action

At one of Europe’s most advanced plastics sorting facilities, recycling meets digital technology. The operator handles around 90,000 tonnes of plastic waste per year, separating it into 13 material streams such as PP, PE, PET, metals, and paper. Alongside its core sorting work, the facility offers a unique RFID packaging testing service for brand owners.

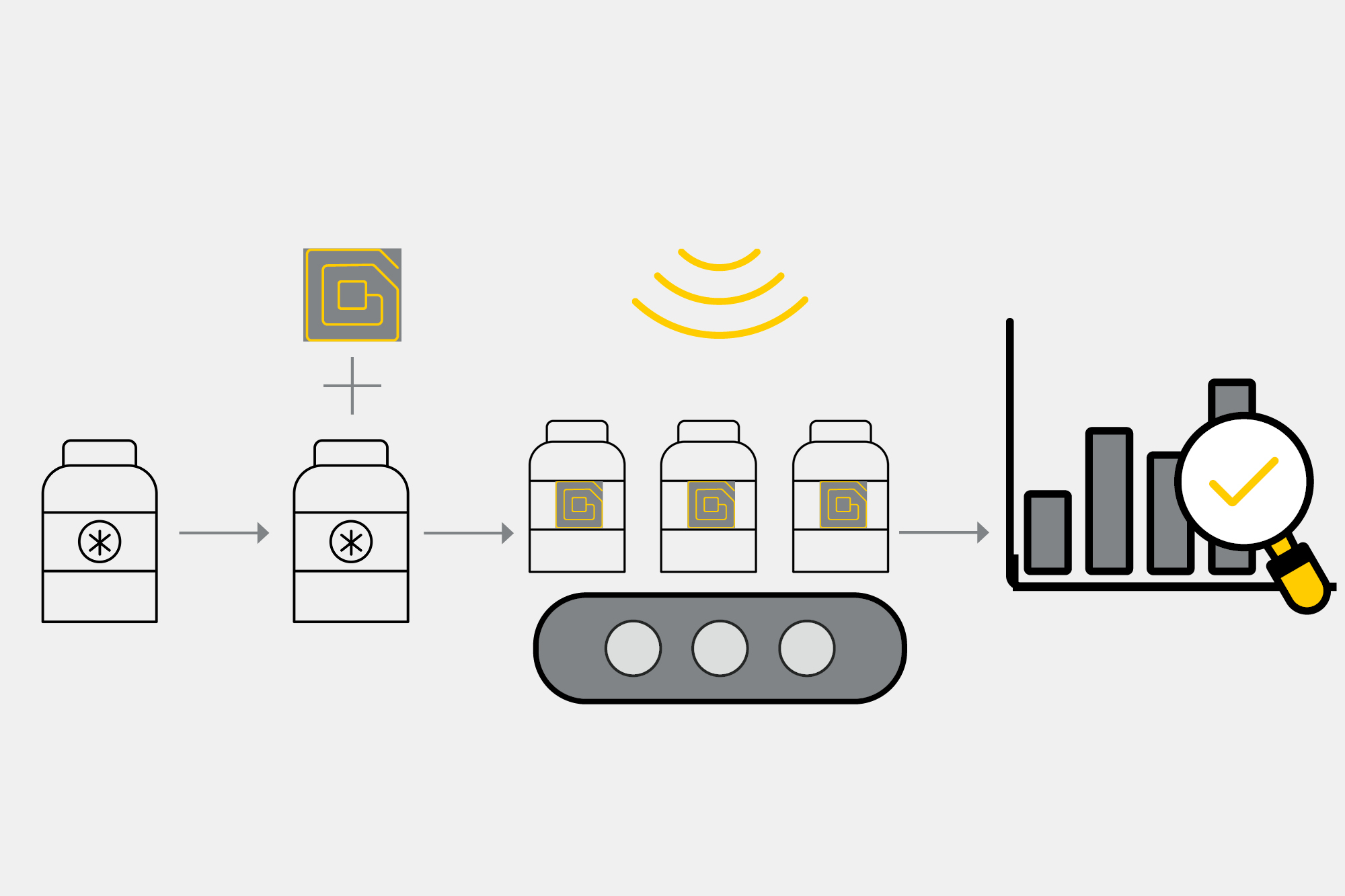

Here’s how it works:

- A brand owner sends 100 samples of a new packaging design.

- Each sample is RFID-tagged and released into the normal waste stream.

- RFID readers along the line track how each package moves through the sorting process.

- The data is compiled into a detailed report showing whether the design was sorted correctly, both at the level of individual items and the full batch.

For brand owners, the benefit is clear: they get data-driven feedback on recyclability before launching a package to market. If the results show problems, designers can adjust materials or construction so the package flows into the correct recycling stream. In other words, RFID packaging testing turns recyclability from guesswork into measurable performance.

This service is used month after month by businesses in food, cosmetics, pharmaceuticals and beyond — and it shows how technology can help close the gap between EU recycling rules and real-world outcomes.

Europe Takes Action: From Directives to Daily Habits

Europe is setting the pace on plastic waste reduction. From high-level directives in Brussels to bag taxes in supermarkets, rules and incentives are reshaping how packaging is designed, sold, and recycled. For businesses, this means recyclability is no longer optional — it’s becoming a license to operate.

The EU’s Single-Use Plastics Directive already requires PET bottles to contain 25% recycled content by 2025 and 30% by 2030. New agreements go further, setting tougher targets and bans on certain single-use items.

Across member states, local initiatives — from deposit systems to bag taxes — are changing how people shop, return bottles, and handle packaging waste.

RFID Drives a Future with Less Waste Through Circular Innovation

Imagine a world where packages don’t just carry goods but also their own recycling path. RFID is already bringing that vision closer. Think for instance:

- Reusable cups at festivals and city events: Across Europe, drinks are often served in returnable cups with a deposit (Pfand). With RFID tags, returns become seamless: drop the cup into an automated station and get your deposit back instantly.

- Expiry management in food & beverage: By supporting first-expired-first-out (FEFO) models, RFID can track true shelf life instead of static best-before dates, helping cafés and stores reduce food waste.

- Smart packaging with embedded data: RFID labels can carry information on origin, handling, or even storage conditions like temperature or humidity — making logistics more transparent and efficient.

- Reducing supply chain losses: Item-level visibility prevents shrinkage, misplacement, and overproduction, saving costs and resources alike.

- Circular economy feedback loops: Data from RFID-enabled packaging can guide brand owners in redesigning packaging, improving recyclability, and keeping plastics in circulation longer.

You might also find these interesting

case

RFID in Waste Sorting

Veolia’s plastics sorting facility uses RFID to test new packaging designs in real waste streams. The results give brand owners data-driven insights to redesign packaging for better recyclability and compliance with EU rules.

article

The waste we do not see

Avery Dennison and Turck Vilant Systems discuss waste sorting further, by asking if RFID can help unlock intelligent recycling at scale building on the Circpack by Veolia.