Automated RTI Pool management - reduce losses, boost asset turns

RFID- or RTLS-enabled RTI Pooling solutions ensure full transparency, faster pool turnaround times and cost-friendly pool management.

A short introduction to RFID- / RTLS-based RTI Pool Management

Digitally managed RTI pools offer greater cost-efficiency and faster asset turnaround. Our tracking solution delivers real-time visibility into the availability of pallets, crates, and roll cages—reducing idle time and loss. In addition, the system’s usage data enables accurate daily rate billing, supporting fair and efficient pool operation.

The Turck Vilant Systems RTI Pooling Solution

In shared logistics loops, multiple actors often rely on a common pool of RTIs (Returnable Transport Items). However, these pools become inefficient when the pool owner lacks visibility into the location and status of each asset. High capital costs are common, as RTIs are frequently lost, broken, or not returned on time.

Turck Vilant Systems’ RFID- and RTLS-based tracking solution brings full transparency to RTI movement. We automatically record when items are dispatched to customers, track RTIs at customer sites, and monitor those undergoing maintenance. This end-to-end visibility reduces losses and significantly improves operational control.

By eliminating blind spots, pool owners avoid unnecessary investments in new RTIs, benefit from faster turnaround times, and achieve higher utilization of existing assets.

With over 20 years of experience in asset tracking—covering pallets, crates, roller cages, bins, and more—we support RTI owners from the initial RFID tagging all the way to real-time asset visualization on a digital map.

Turck Vilant Systems Solution for RTI Pool Handling

- Assigns a unique identity to assets in the pool (crates, pallets, roller cages, bins, containers).

- Records asset whereabouts.

- Ensures a timely delivery of RTIs to customer.

- Visualizes asset location on a map.

- Logs all RFID events and documents the history of each individual asset.

- Produces data for invoicing.

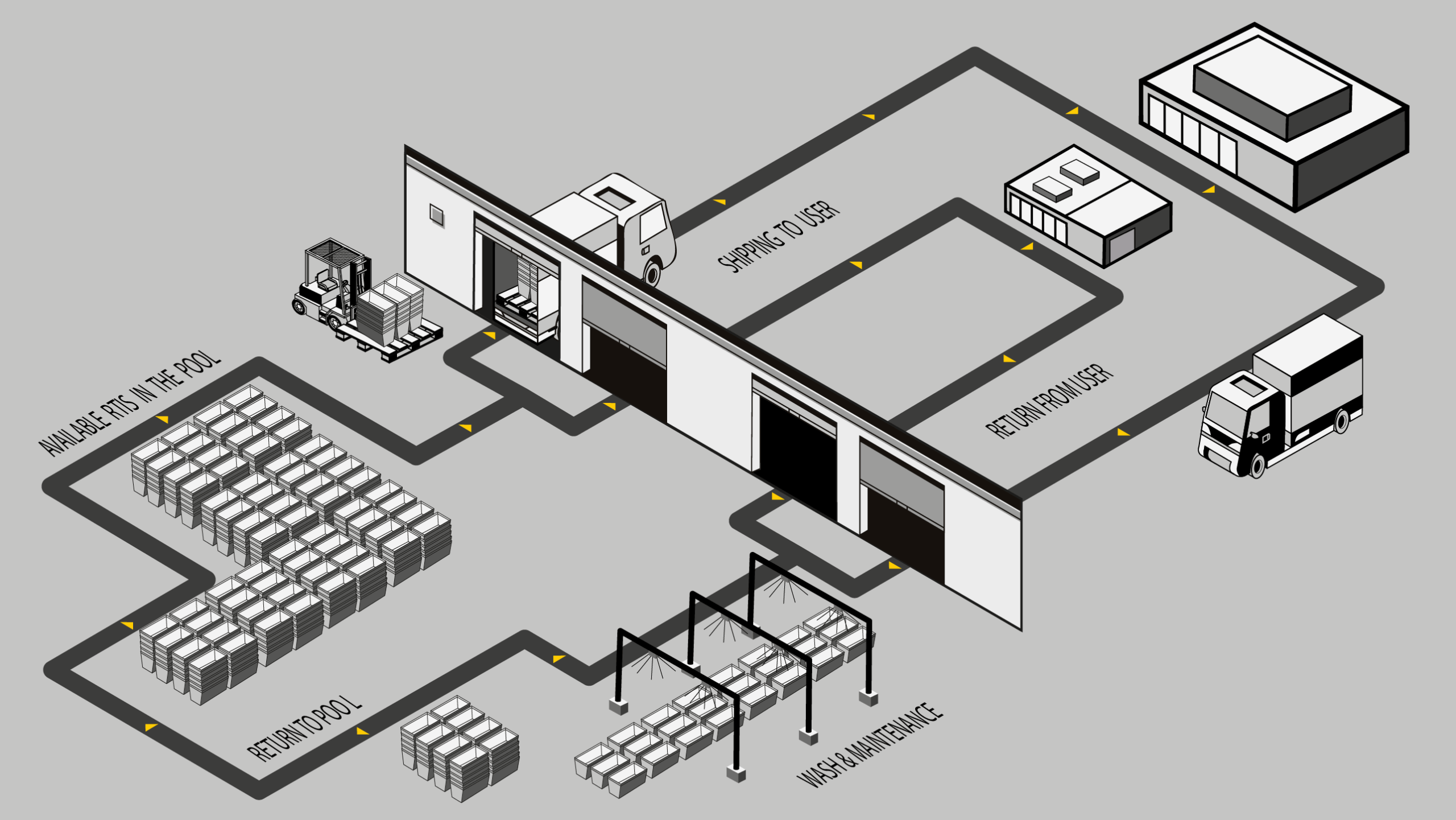

A Step-by-Step Approach to RTI Tracking

Strategically placed RFID read points or RTLS locators across dispatch areas, customer locations, and service hubs provide real-time visibility into RTI movement and availability. When integrated with logistics operations, each handoff, return, or maintenance cycle is automatically recorded—eliminating manual tracking, reducing loss, and enabling higher asset utilization.

Free RTIs in the Pool

New RTIs / assets are generated to the pool and marked as available in the system.

Shipping

As RTIs are loaded for transport, their status is changed to shipped and their destination is recorded.

Tracking in the Hub

The RFID System can be extended to partner areas or logistics hubs to record inbound and outbound shipments of RTIs.

Customer Returns

The RFID system automatically registers the returning RTIs back and waiting for inspection and maintenance.

Wash and Maintenance

Returned RTIs undergo an inspection, and when needed, maintenance or wash processes are initiated.

Return to Pool

After wash & maintenance RTI status is changed as available in the pool and it can be shipped to customer again.

Free RTIs in the Pool

New RTIs / assets are generated to the pool and marked as available in the system.

Shipping

As RTIs are loaded for transport, their status is changed to shipped and their destination is recorded.

Tracking in the HUB

The RFID System can be extended to partner areas or logistics hubs to record inbound and outbound shipments of RTIs.

Customer Returns

The RFID system automatically registers the returning RTIs back and waiting for inspection and maintenance.

Wash and Maintenance

Returned RTIs undergo an inspection and when needed, maintenance or wash processes are initiated.

Return to Pool

After wash & maintenance RTIs status is changed as available in the pool.

Solution benefits

24/7 visibility on RTIs

Reduces loss of assets by 10%

Faster pool turnaround and higher usage rates

Automated Invoicing data

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.