Optimizing Logistics: Reducing Errors with RFID and RTLS for a Sustainable Future

What makes a supply chain sustainable?

A supply chain is only as sustainable as its weakest link, states Björn Feldhaus, a long-term technology consultant, Logistics Developer by trade, and Turck Vilant Systems RFID expert. He emphasizes that the primary task of a logistician is to move an object from point A to point B as quickly and cost-efficiently as possible. Therefore, a supply chain where each step is optimized to its full potential can be considered sustainable.

However, the reality of logistics transportation’s reliance on fossil fuels means that shipment errors directly contribute to avoidable CO₂ emissions and significant financial loss. These errors lead to additional mileage and waste, impacting both manufacturing and logistics companies. This article summarizes our white paper that explores how advanced track-and-trace solutions, particularly identification technologies like RFID and RTLS, can mitigate these adverse effects by resolving common logistical challenges and promoting sustainability. Central to achieving this is the recognition that anything hindering the smooth and efficient movement of an object from point A to point B in the supply chain must be streamlined. This focus on process optimization is crucial for building a truly sustainable and efficient operation.

The Hidden Costs of Inaccuracy

Current supply chains face substantial challenges from inaccurate data. Studies reveal significant discrepancies between recorded inventory and physical stock, leading to considerable profit reductions and diminished efficiency. Misidentification, misplaced, or lost items result in costly reshipments, wasted resources, and increased emissions.

Errors in transportation, such as misidentification of items, result in additional mileage and, consequently, increased CO₂ emissions.

Common symptoms of inefficient logistics include unidentifiable items in loading zones, missing customer orders, items delivered to incorrect locations, and the inability to locate products despite system availability. These issues often stem from critical errors such as wrong items shipped, items left out of shipments, deliveries sent to incorrect destinations, or items shipped without proper scanning.

Pinpointing the Root Causes of Shipment Errors

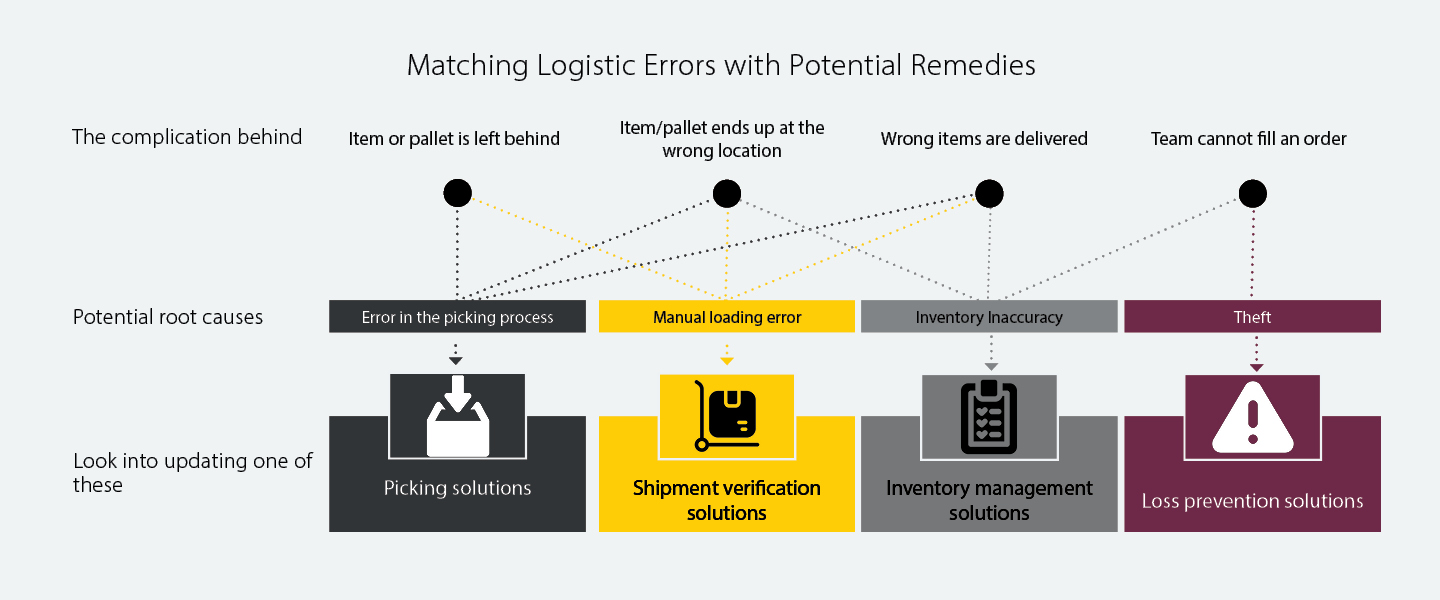

A sustainable supply chain relies on efficient and accurate movement of goods. However, discrepancies in the supply chain are a primary driver for companies investing in track-and-trace solutions. According to our experience, such complications are often caused by:

- Manual errors, potentially corrected by automation.

- Issues with the current process, usually improvable by re-defined methods

- Communication breakdowns caused by a lack of communication between departments, suppliers, carriers, and customers in the network, and are best fixed by denser communication.

- External factors, that organizations cannot affect.

Introducing any tracking technology to support company processes can help automate processes and collect valuable data, which addresses the first two issues. The root causes of supply chain discrepancies and their potential resolutions are discussed in more detail within our white paper. For insights into remedies pertaining to manual errors and process issues, please refer to the image below.

Technology as a Catalyst for Change

While process adjustments are sometimes necessary, technology excels where human limitations exist, particularly in managing large volumes of data and ensuring accuracy. Track-and-trace systems bridge the gap between the physical world and IT, transforming raw data into actionable insights and supporting core business processes.

Our paper outlines various solution approaches for optimizing logistics, including:

- Picking Solutions: Guiding accurate item collection.

- Shipment Verification: Automatically matching order contents with actual shipments.

- Inventory Management: Enhancing stock accuracy and traceability.

- Loss Prevention: Identifying and preventing shrinkage.

Optimizing Logistics Means Choosing between Barcodes, RFID, GPS and RTLS

The effectiveness of track-and-trace hinges on selecting appropriate identification technologies:

- Barcodes/2D Codes: Widely used, but require line-of-sight and individual scanning, making them prone to manual error.

- RFID (Radio Frequency Identification): Offers long-range, automatic, simultaneous reading of multiple identifiers, greatly enhancing data capture efficiency and reducing human error.

- Active Tracking Technologies (RTLS, BLE, GPS): Provide highly detailed location information, enabling automatic, continuous tracking for precise asset whereabouts.

Optimizing logistics often needs a combination of different AIDC technologies (e.g. barcodes or RFID on item or asset level) and active tracking (e.g. GPS or BLE on pallet or shipment level). According to our experience this usually is the most cost-effective solution.

Conclusion

Understanding the root causes of shipment inaccuracies and the appropriate technological approaches is critical for supply chain optimization. Download the full white paper by filling the form below for a deeper dive into these issues, a comprehensive analysis of identification technologies, and insights into how digitized logistics can lead to more sustainable and efficient operations.

Download White Paper

Unlock expert insights into optimizing your supply chain. Our team has put together this white paper to help you understand how track and trace systems can be applied to enhance efficiency and sustainability in your operations.

You can also find the direct contact details of our Sales team here.