Track & Trace Platform

Deploying suitable RFID and RTLS devices and applications at strategic junctions, they power the system to track materials, inventory, and assets.

Comprehensive Track & Trace Platform Empowers Educated Decisions

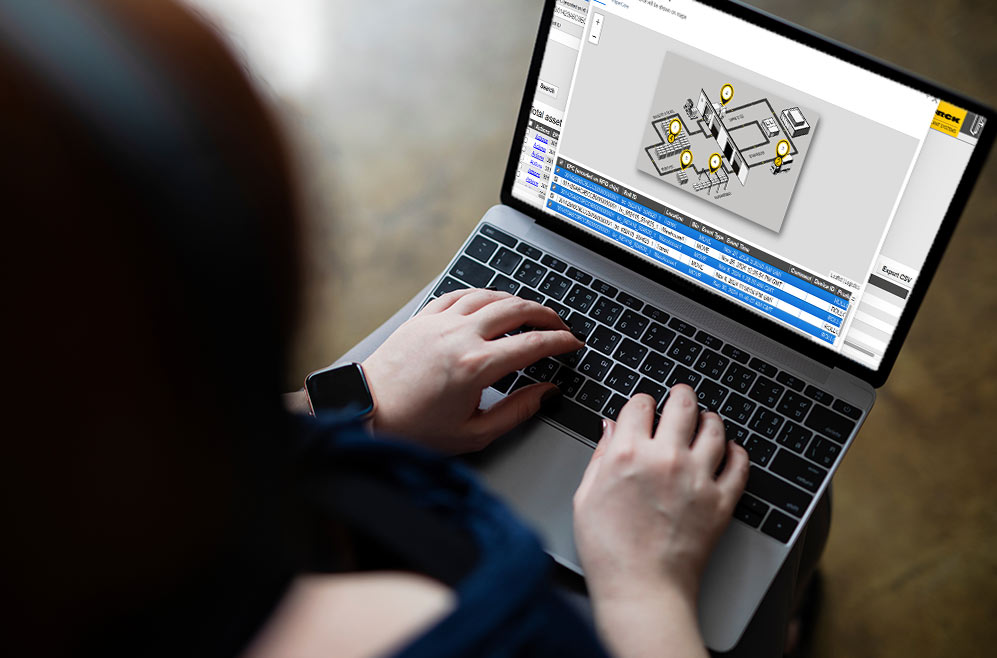

Our in-house developed track & trace platform features an intelligent RFID system. This core system seamlessly integrates with active tracking elements, such as BLE (Bluetooth Low Energy), GPS, or other IoT equipment when needed, forming a comprehensive solution for real-time asset visibility.

Our solution assigns unique identities to finished products or production batches, enabling automatic monitoring of their warehouse location, availability, and shipment status. We deploy RFID, sensors, and other IoT devices on dock doors, forklifts, mobile devices, and conveyor belts to precisely track individual products, boxes, roller cages, or pallets used for shipping. This robust system ensures the accurate picking, use, and shipping of correct items throughout the process.

Our Platform

Our in-house developed track & trace platform features an intelligent RFID system that seamlessly integrates with active tracking elements like BLE (Bluetooth Low Energy), GPS, or other IoT equipment as needed. These RFID and IoT-based solutions bridge the gap between the physical and company IT worlds. For instance, where an IT system might lack visibility into production or warehouse operations, our system verifies the use of correct materials and tools during production ramp-up.

Our solution assigns unique identities to finished products or production batches, enabling automatic monitoring of their warehouse location, availability, and shipment status. To achieve this, we deploy a mix of identification technologies—including barcodes, RFID, RTLS, and GPS—across diverse reading environments such as forklifts, gates, tunnels, conveyor lines, and mobile devices. All collected data from these varied sources precisely tracks individual products, boxes, roller cages, or pallets used for shipping, reporting to a central middleware that processes, consolidates, and transforms it into actionable insights for business decisions. This robust system ensures the accurate picking, use, and shipping of correct items throughout the process.

Key Use Features of our Track & Trace Platform

- Support on a wide range of identification and locationing technologies including UHF RFID, barcodes and 2D codes, UWB, BLE, GPS

- Diverse use cases and usage environments with industrial equipment.

- Centralized data processing and consolidation.

- Actionable insights for business decisions.

- Accurate tracking of individual items.

- Seamless integration with existing IT systems.

Our Track & Trace Platform

Forklifts and Payloaders

An intelligent track and trace application knows what a forklift carries on its fork and tracks the location of the items automatically.

RFID Gates

With automatic direction detection for inbound and outbound goods, the RFID Gate from Turck Vilant Systems keeps your inventory constantly up to date.

Mobile Devices

Mobile RFID applications extend the technology capabilities everywhere. Users carry data on stock levels and quality in their pocket.

RFID Tunnels

Turck Vilant’s RFID tunnel registers every item flowing through it—by conveyor or by hand—and updates your systems in real time.

Printers

The key to working RFID systems is the tags, often encoded and generated with industrial printers.

Track & Trace Middleware

Track & Trace Middleware from Turck Vilant Systems collects data from and remote manages RFID devices. Collected data integrates with customer IT-systems.

Applications

RFID software from Turck Vilant Systems comprises 30+ ready applications that we can configure to serve a given customer use case.

RFID Tracking

The core of Turck Vilant Systems’ Track & Trace Platform relies on data from various identification devices, including barcode and RFID readers, and mobile phones, all utilizing in-house developed data capture applications.

Information gathered by our data collection software from these RFID touch points is then centralized within our middleware for seamless integration with customer IT systems.

Locating extended with RTLS

When the need for highly accurate item whereabouts arises, RTLS (Real-Time Location Systems) locators become indispensable. These systems serve as a powerful extension to our existing RFID system, offering superior precision in pinpointing item locations. Crucially, RTLS goes beyond mere horizontal positioning in warehouses, also providing vital data on an item’s height, enabling true 3D location tracking. This allows for the seamless mixing of precise location data from RTLS with detailed product data still collected via RFID, creating a comprehensive view of assets.

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.

Read More

integration

Bridging End-to-End Traceability

Our track and trace platform supports a wide level of options for the integration of RFID and RTLS technologies.

Product

Consolidating Data for Actions

Track & Trace Middleware from Turck Vilant Systems collects data from and remote manages RFID devices and printers.

Product

Data Collection Applications

RFID software from Turck Vilant Systems comprises 30+ ready applications that we can configure to serve a given customer use case.