Shipment Accuracy Guaranteed with RFID

RFID ensures error-free deliveries to automatic shipments

Short Introduction to Shipment Verification with the Help of RFID

An intelligent RFID system checks shipment details against a pick list ensuring high accuracy and faster loading.

The Turck Vilant Systems Solution for Verifying Shipment Contents

It is crucial that shipping and loading of deliveries happens at speed especially in peak hours. To expedite the process, the correctness of the shipment can be verified already at the packing phase. When picking and packing single handling units to a shipment, RFID is used to automatically identify item level tagged products, and to verify that all needed products have been added to this shipment.

The Turck Vilant Systems RFID-based shipment verification streamlines and secures the entire chain from receiving a pick list to loading the delivery. This speeds up the process, removes all manual errors, cuts down stock turnaround time and increases customer satisfaction just to mention few of the advantages.

Turck Vilant Systems Solution for Shipment Verification

- Gives a unique identity to shipments or handling units

- Keeps record of items belonging to a shipment

- Ensures delivery accuracy by verifying that correct products are loaded

- Logs all RFID events and documents the history of each individual shipment or handling unit.

How to implement RFID enabled Shipment Verification

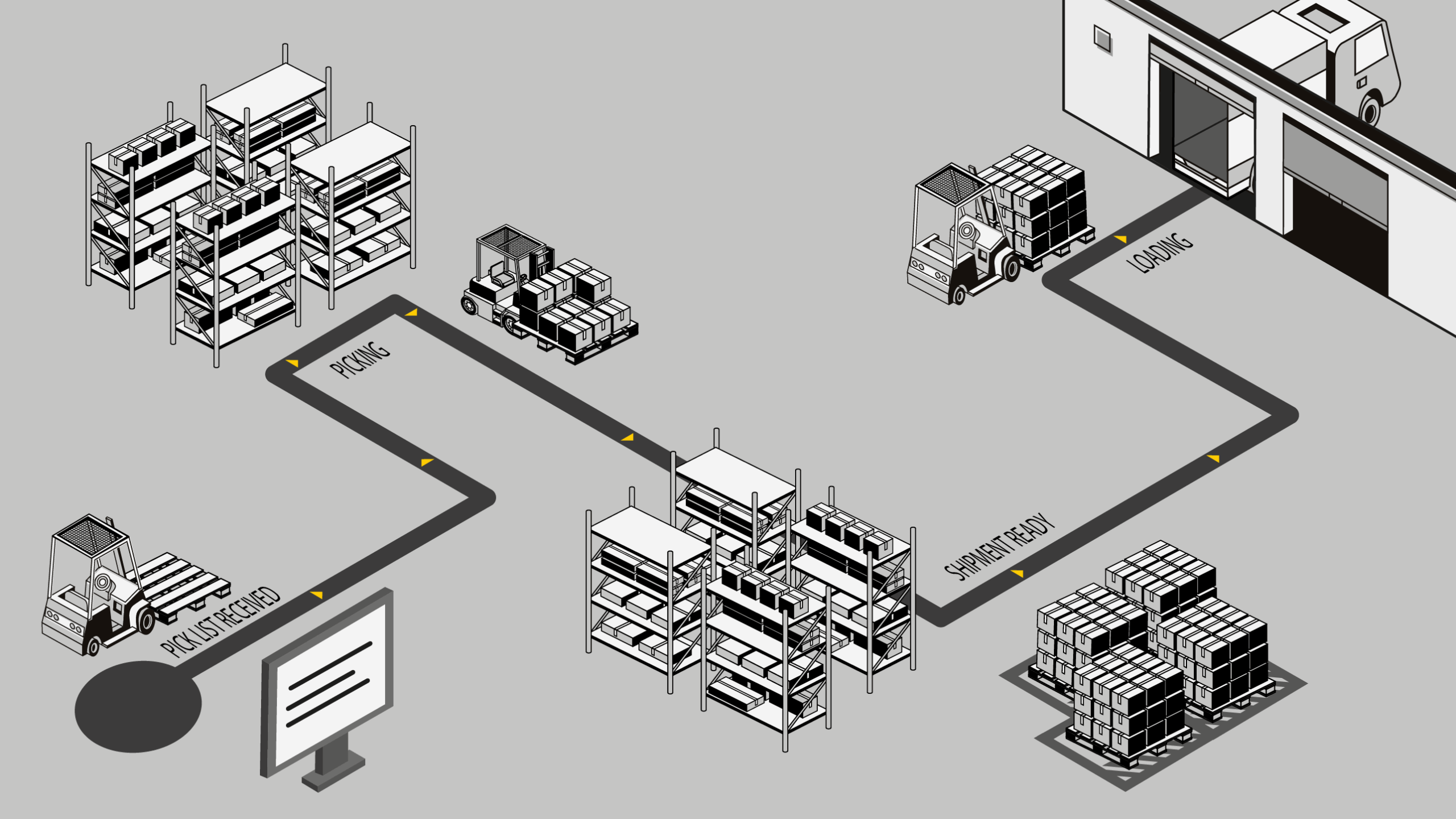

Implementing RFID read points to correct areas within the warehouse and shipment area ensures only correct items are picked, packed and shipped. Furthermore, the system verifies that nothing is left behind.

Pick List

Customer business systems (such as WMS/ERP) provides the RFID system with a pick list for shipping.

Picking

The RFID system checks the picked items against the pick list to ensure only correct items are picked.

Shipment Ready

Ready pallets are parked at the parking area for the creation of shipping documents and when necessary additional RFID tag processing.

Loading

As the pallets are loaded to trucks, the RFID system verifies that correct handling units are moved trough correct dock doors.

Pick list

Customer business systems (such as WMS/ERP) provides the RFID system with a pick list for shipping.

Picking

The RFID system checks the picked items against the pick list to ensure only correct items are picked.

Shipment Ready

Ready pallets are parked at the parking area for the creation of shipping documents and when necessary additional RFID tag processing.

Loading

As the pallets are loaded to trucks, the RFID system verifies that correct handling units are moved trough correct dock doors.

Solution benefits

No-touch loading enabled

Zero manual errors

Decrease in costs of claims

Saves administrative time

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.