How Pallet Tracking Stops the Hidden Loss Draining Global Supply Chains

Pallets are the invisible backbone of global supply chains. They move across borders, sit in trucks, and deliver food, clothing, and medicine. Yet, somewhere along the journey, they disappear. Every year, millions of pallets quietly vanish, break, are discarded, or simply go missing.

Across Europe and the United States alone, an estimated 33 million pallets are lost each year. At an average value of €14 per pallet, that’s more than €450 million in wasted material — roughly equal to the annual budget of Finland’s Ministry of the Environment. Details behind the calculation

The Hidden Reasons Behind Wooden Pallet Loss

Why millions of pallets disappear every year — and why it’s not just about theft or damage.

Every summer in Craigyhill, Northern Ireland, thousands gather to build one of the world’s largest bonfires — out of more than 17,000 wooden pallets. It’s a striking sight and a symbol of how easily we undervalue these everyday tools of global trade. When pallets are seen as disposable, that same mindset quietly spreads through supply chains worldwide.

Beyond symbolic bonfires, pallet loss happens every day for more practical — and preventable — reasons.

- Undervalued assets: Pallets are often treated as cheap, replaceable logistics tools. Because they’re seen as low-value items, few people track them — and even fewer take ownership for their recovery.

- Missing return routes: Especially in B2C and last-mile deliveries, pallets simply don’t make their way back. Without structured reverse logistics, loss becomes part of the process rather than an exception.

- No clear ownership: In most organizations, no single team “owns” the pallet fleet. Costs sit between procurement, logistics, and operations — meaning no one feels directly responsible for minimizing waste.

- Breakage and theft: Some pallets inevitably get damaged or stolen. But without visibility into when and where that happens, companies can’t separate normal wear-and-tear from preventable loss.

The Real Cost of Pallet Loss in Global Supply Chains

The result is strikingly similar to the Craigyhill bonfire — only less visible. Each year, companies burn millions in lost pallets, wasted wood, and unnecessary emissions. Just consider these three aspects to waste:

Environmental

🌳🌳🌳

Every year, replacing lost pallets consumes roughly 900,000 tonnes of wood — the equivalent of more than 1.5 million trees.

On top of the timber itself, the disposal and burning of damaged or unreturned pallets generate avoidable CO₂ emissions, adding to supply chain footprints that companies are trying to reduce.

By closing the pallet loop through tracking and reuse, companies contribute directly to circular economy principles: fewer trees cut, less waste burned, and smaller carbon footprints.

Operational

⚙️⚙️⚙️

Lost pallets don’t just cost money — they slow down the flow of goods. When shipments arrive short on pallets, loading times increase, warehouse space gets misused, and the lack of visibility disrupts planning and inventory accuracy.

Over time, these small inefficiencies accumulate: delayed dispatches, extra handling, and even strained relationships between suppliers, manufacturers and retailers.

In supply chains operating on razor-thin margins, these small inefficiencies compound over time, quietly eroding competitiveness across industries.

Financial

💰💰💰

A retail distribution center in Scandinavia ships and receives around 3,000 pallets daily, or roughly 650,000 per year.

Before introducing RFID-enabled, durable pallets made of composite or plastic materials, the company lost 20–40 wooden pallets every day — a total of more than 10,000 annually.

At an average cost of €9.50 per pallet, that meant over €100,000 each year burned on replacements alone — not counting the extra labor, transport, and administration involved in managing the losses.

When the company switched to traceable, rugged pallets, losses dropped close to zero — proving how quickly visibility translates into measurable savings.

Counting Pallets Like It’s Still 1999

For most companies, pallet management hasn’t changed much since the late 1990s. Manual logs, spreadsheet inventories, and periodic audits are still the norm — despite billions of pallets moving through highly digital supply chains. The result? Data gaps, missing assets, and reactive fixes instead of real prevention.

For companies that ignore their pallet pool, the cost isn’t limited to replacement fees. Consider:

Manual processes don’t scale. Paper records and spreadsheets rely on human accuracy — and humans make errors. When you’re shipping thousands of pallets a day, those small errors multiply quickly.

Poor visibility means poor accountability. Without live data, it’s impossible to see where pallets are or who’s responsible for them. That lack of visibility turns recovery into guesswork and finger-pointing.

Reactive, not proactive. Most companies only notice pallet loss when shortages appear or audits flag discrepancies. By then, the money — and the pallets — are already gone.

You can’t manage what you can’t see — yet most supply chains still treat pallets as invisible.

And that invisibility is exactly what keeps the losses alive. Traditional methods weren’t built for global, data-driven logistics — but modern pallet tracking is. With real-time visibility, automation, and accountability, companies can finally see every pallet for what it is: an asset, not an afterthought.

Modern Pallet Tracking Solutions Enforce Visibility

Modern pallet tracking builds on RFID and RTLS technologies to make pallet and RTI movements visible in real time. While it can be applied to wooden pallets, the biggest benefits come from using durable plastic or composite pallets, crates, and trays with a lifespan of up to 15 years — a more sustainable and efficient foundation for closed-loop logistics.

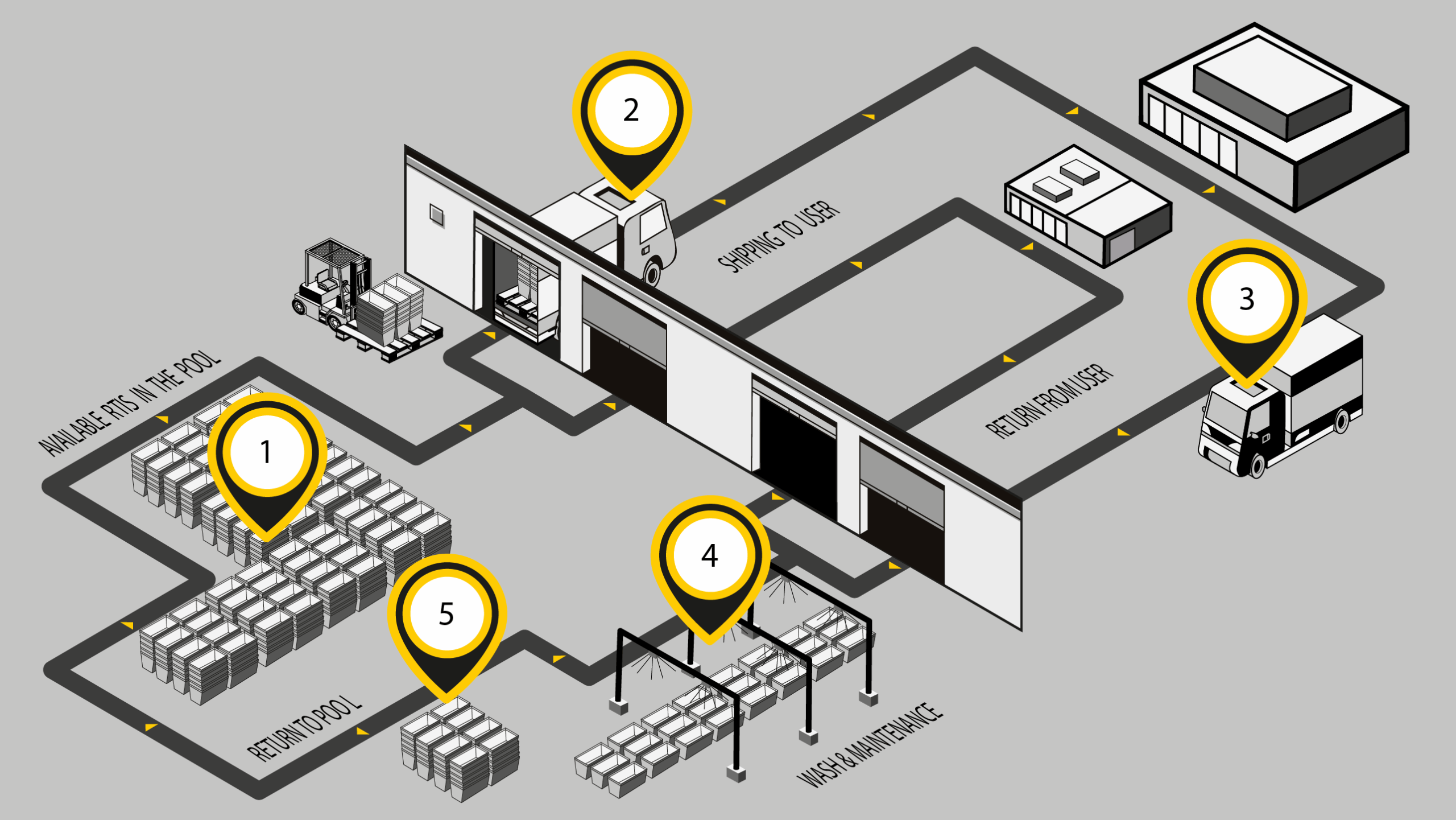

The Turck Vilant Systems pallet tracking solution connects every stage of the RTI loop — from depot loading to return and maintenance — by introducing RFID or RTLS checkpoints at key locations. These tagged points provide real-time visibility, ensuring each pallet, crate or tray is traceable throughout its lifecycle.— by introducing RFID or RTLS checkpoints at key locations. These tagged points provide real-time visibility, ensuring each pallet or tray is traceable throughout its lifecycle.

Pallet Tracking - FAQ

What’s the difference between RFID and RTLS tracking?

Can pallet tracking be used with wooden pallets?

Yes — pallet tracking can be applied to wooden pallets, though the choice of technology matters. We generally recommend RFID over RTLS, as the cost of individual RTLS tags can be relatively high compared to the value of each wooden pallet.

RFID offers a practical balance between cost, accuracy, and scalability, making it the preferred option for tracking large wooden pallet pools.

How long does it take to see ROI from pallet tracking?

The payback period depends on fleet size, current loss rate, and how quickly the system is rolled out. Peer-reviewed research on RFID and RTI tracking confirms consistent cost savings through reduced labor, fewer lost assets, and improved operational accuracy, though few studies publish exact ROI timelines due to commercial sensitivity. Source

In practice, companies we work with typically see measurable savings within 6–12 months, and full ROI within 18–24 months — particularly in shared asset pools where greater pallet availability translates directly into faster turnaround times and more reliable deliveries.

Furthermore, pool managers gain precise visibility into asset location and utilization, allowing them to charge rental fees based on real data from RFID or RTLS events. This creates a fair and transparent system: pool users pay only for the actual time assets are in use, while managers maximize efficiency and return on each pallet in circulation.

What environmental benefits does pallet tracking provide?

Pallet tracking helps companies lower their environmental impact by keeping assets in circulation longer and ensuring that every shipment moves efficiently. In customer deployments, loss rates have fallen below 0.2%, thanks to clear ownership and accountability created through tracking data.

With verified dispatch processes, companies can confirm that every pallet is sent to the correct location, preventing unnecessary transport and the emissions linked to mis-shipments. At the same time, the improved visibility encourages faster returns and higher asset turnover: when all participants know where pallets are, they are returned sooner and fewer spare assets are needed to cover gaps.

A smaller, faster-moving pool means less material in circulation, less wood or plastic consumed, and lower overall CO₂ emissions — a direct contribution to circular economy practices and corporate sustainability goals.

How does pallet tracking integrate with existing ERP or WMS systems?

In most cases, integration with existing ERP or WMS systems is straightforward — provided those systems already manage pallet or RTI data. However, some ERPs and warehouse systems don’t natively track individual pallets, which is where the RFID or RTLS platform adds real value.

When native support isn’t available, the tracking system can operate as a standalone data layer, feeding key information — such as pallet availability, non-returns, and usage for invoicing — back to the ERP or other business tools through standard APIs or data exports.

In this setup, the pallet tracking system effectively becomes the source of truth for asset movement, while your ERP or WMS continues to handle orders, inventory, and financials. The result is a seamless flow of data without disrupting existing processes.

How can I get started

The first step is to map your pallet or RTI flows — understanding how many assets you manage, where losses typically occur, and which processes would benefit most from automation.

From there, our team helps design a pilot or proof-of-concept using RFID or RTLS technology, depending on the asset type and environment. The goal is to validate the business case quickly — both operationally and financially.

Once results are verified, scaling is straightforward. Existing ERP or WMS systems can be connected to the tracking platform to create full visibility and data flow across your operations.

👉 If you’d like to explore what a tailored solution could look like for your supply chain, our experts can guide you through the first steps. Click here to book a free online evaluation.

Related Case Stories

CASE

RFID ensures timely deliveries

A third-party logistics provider relies on RFID and camera systems to streamline the shipment process and provide proof of pristine delivery.

case

RFID manages RTI pools

Building its returnable transport item (RTI) pool with RFID from the start, this logistics provider offers a CO2-friendly solution that boosts operational efficiency

The Numbers Behind

Our estimate of the annual pallet loss is based on available industry data from both Europe and the United States.

The European market has approximately 3.2 billion pallets in circulation, while the U.S. market adds around 2 billion. Across these regions, the combined annual loss rate is roughly 1 %, equivalent to about 33 million pallets disappearing from use each year.

With an average replacement value of €14 per pallet, that results in more than €450 million in lost material value annually — and that’s before considering handling, transport, and administrative costs associated with replacements.

When environmental and operational factors are included, the true global cost of pallet loss easily exceeds a billion euros every year.

Sources

- European Federation of Wooden Pallet & Packaging Manufacturers (FEFPEB), Annual Report 2021 – European pallet production and circulation volumes.

- National Wooden Pallet & Container Association (NWPCA, U.S.), Industry Statistics 2022 – U.S. pallet market size and recovery data.

- U.S. Environmental Protection Agency (EPA), Advancing Sustainable Materials Management – 2021 Fact Sheet – Pallet recovery and landfill volumes.

- FEFPEB & EPAL, European Market Data 2021 – Estimated pallet loss and reuse rates.

- Internal analysis by Turck Vilant Systems, based on aggregated industry data and average market pricing for wooden pallets (2024).

Download White Paper

Unlock expert insights into digitizing your sales and supply chain. Our team has put together this White Paper to give you insights and best practice tips.

You can also find the direct contact details of our Sales team here.