How to Choose the Right Technology: From RFID to RTLS Asset Tracking and Beyond

Supply chains are becoming increasingly data-driven, yet many companies still struggle to see where their assets really are. Barcodes, RFID, GPS, and RTLS asset tracking each promise visibility — but in very different ways. Understanding the key benefits of each technology, and where to apply them, is essential to avoiding costly blind spots.

Technology Alone Doesn’t Solve Visibility Gaps

Visibility underpins a modern supply chain, yet many companies still face blind spots in asset tracking. Misplaced or misidentified items, delayed shipments, and unrecorded movements all carry hidden costs — from wasted time and extra transport to excess emissions. Choosing the right tracking technology is not just about hardware; it’s about addressing these root causes and ensuring your data-capture fits your operations.

Our RFID experts start by visiting customer sites to uncover bottlenecks and root causes — not to add tools for their own sake. Many issues appear where ERP or WMS data ends, since accuracy depends on what people record. We focus on making those human actions visible first. Once the causes are clear, the right technology becomes an enabler — for more insight, read our article Optimizing Logistics: Reducing Errors with RFID and RTLS and download the detailed white-paper.

Tracking Technologies at a Glance

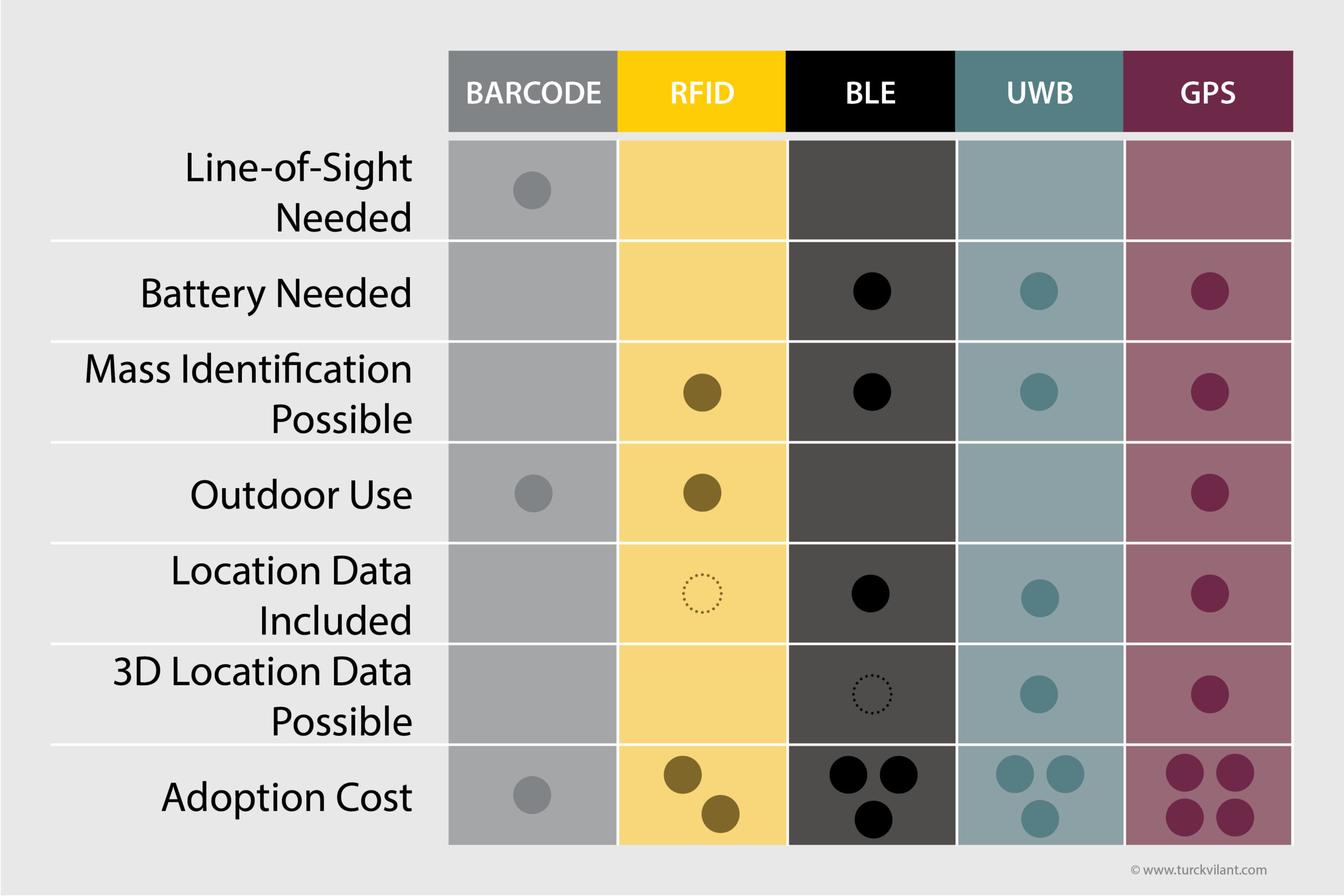

Choosing the right identification method starts with understanding what each technology can — and can’t — do. From barcodes that still dominate packaging lines to RTLS asset tracking that delivers real-time location data, every approach balances accuracy, range, and cost differently.

The comparison below highlights their core characteristics at a glance.

Passive Tracking

Passive identification methods such as barcodes and RFID have long formed the backbone of asset-visibility systems. They work at fixed readers and checkpoints, and they offer low-cost, reliable tracking for large volumes of returnables and containers. Their simplicity and high throughput make them ideal for structured logistics operations.

Active Tracking

Active technologies such as BLE and UWB deliver continuous, real-time visibility within defined areas, while GPS extends tracking outdoors and across long distances. BLE and UWB are part of RTLS (Real-Time Location Systems) — technologies that automatically determine an asset’s position without manual scanning. Together, they enable seamless visibility from warehouse to field, at a cost that now makes RTLS asset tracking viable for operations of all sizes.

Want to go deeper into how each technology works and where it delivers the most value? Our Track & Trace Guidebook explains the strengths, limits, and ideal use cases of barcodes, RFID, BLE, UWB, and GPS in modern supply chains.

RFID or RTLS Asset Tracking - which is the best fit?

RFID and RTLS share a common goal — to make assets visible without manual input — but they achieve it in different ways. RFID captures movement data at defined read points — or continuously when readers are mounted on forklifts or other mobile equipment — providing reliable event history for every asset handled. RTLS, by contrast, tracks tagged items automatically within a defined area, showing where they are at any moment.

The right choice depends on process flow and data needs. RFID excels in structured, high-volume logistics where assets move through known paths, while RTLS adds value when locations change frequently or manual handling makes fixed points impractical. In most operations, the best fit isn’t one or the other — it’s a combination. RFID delivers the foundation for automated identification; RTLS extends it with continuous, real-time visibility where it matters most.

Spotlight — RTLS Goes Mobile with BLE

Real-time tracking has long been associated with large depots and fixed infrastructure. That’s changing fast. Bluetooth Low Energy (BLE) brings RTLS out of the warehouse and into the hands of every operator — making continuous visibility possible even for small users and remote locations.

In a typical RTI pool, one owner manages hundreds of thousands of assets across many depots and dozens of partners. BLE-based RTLS allows that central operator to maintain visibility through fixed locators at main sites, while smaller users simply register or confirm assets with a smartphone. In the past, extending visibility to those users wasn’t feasible — installing RFID gates at every collection or delivery point would have been too complex and costly. BLE now bridges that gap, bringing real-time tracking to operators who previously had no access to such smart systems.

BLE enhances RTLS Asset Tracking to offer:

- Hybrid visibility – Fixed BLE locators at depots extended with mobile phones to use for scans at partner sites for complete RTI lifecycle tracking.

- Lightweight participation – Ideal for growers, retailers, or subcontractors handling only a few returnables; allows all pool users to register items, timestamp events, and add product data directly via mobile app.

- Sustainable scalability – Expands real-time visibility across the entire network, complementing existing RFID systems where fixed infrastructure isn’t feasible.

From Evaluation to Execution

Improving visibility starts with understanding where it breaks down. Don’t rush into technology selection before analysing your current processes. Our experts meet customers on-site to uncover bottlenecks, data gaps, and operational needs — the foundation for any successful tracking system. Turning those findings into measurable actions requires careful planning, validation, and long-term support.

Turck Vilant Systems follows a project model designed to give customers full visibility and control throughout implementation. Each phase concludes with a clear checkpoint, allowing you to review results, adjust the plan, or decide whether to move forward.

- Site Survey – We assess current processes, data needs, and environmental factors to define project scope and identify improvement areas.

- Feasibility Tests – Proof-of-concept testing at your site validates technology choices and key performance indicators.

- Pilot – A limited rollout verifies both technical accuracy and user workflows, gathering feedback to refine the full solution.

- Roll-out & Production – Once proven, the system is deployed at scale and integrated with business applications and processes.

- Support – Continuous service and optimization keep the solution reliable and effective long after go-live with 24/7 support available as an option.

You might also find these interesting

case

RFID in Waste Sorting

Building its pool of 90.000 returnable transport items (RTI) with RFID from the start, Recalo, a third party logistics provider offers a CO2-friendly solution that boosts operational efficiency.

RTI POOL MANAGEMENT

RTI pool visibility – stops loss, boosts flow

Digitally managed RTI pools improve cost-efficiency and turnaround through real-time tracking of pallets, crates, and roll cages. The system minimizes idle time and loss while enabling accurate, usage-based billing for fair and efficient operations.

Buyers Guide

Reducing Errors for a Sustainable Future

Navigate the complexities of RFID and RTLS projects with a proven roadmap. Explore our guidebook for expert guidance on successful implementation.

This comprehensive guide discusses technology selection and offers steps for success.