Real-time WIP visibility and smarter rework handling - powered by RFID

RFID- and RTLS-systems or a combination of both automate work-in-progress tracking.

A short introduction to WIP Tracking with RFID / RTLS

RFID- or RTLS-powered WIP (Work in Progress) tracking provides real-time visibility into where each item is in the production flow. By tagging either products or the carriers that move them—whether trays, racks, or skids—the system enables precise stock counts and routes faulty items for rework. This improves quality control, reduces manual effort, and keeps production moving efficiently.

The Turck Vilant Systems Work-in-Progress Tracking Solution

Turck Vilant Systems offers an RFID toolkit that assigns a unique identity to each workpiece. From that point forward, the item is automatically tracked as it moves through key stages of production—whether along the line, during transport on a carrier, or when entering or exiting specific process areas. This continuous tracking supports real-time visibility, ensures accurate process sequencing, and enables early detection of quality issues.

When applied to work-in-progress (WIP) management, the RFID system enhances the ability to locate, route, and monitor parts as they move through production. It logs all movements, captures consumption data, supports rework routing, and eliminates manual errors—resulting in improved process control and production efficiency.

Unlike barcodes or paper-based systems, RFID and RTLS technologies enable hands-free, high-speed identification and location tracking with greater precision, making them ideal for fast-moving, high-accuracy environments.

Turck Vilant Systems Solution for Work-in-Progress Tracking

- Gives a unique identity to each workpiece

- Records workpieces as they move from one workstation to another

- Reports the status of each workpieces

- Logs all RFID/RTLS events

A Step-by-Step Approach to Work-in-Progress Tracking with RFID

Placing RFID read points or using RTLS locators at key production stages and handover points enables real-time visibility into work-in-progress and part quality. As items move through the process, each step is automatically logged—ensuring accurate routing, timely rework handling, and full traceability without manual input or delays.

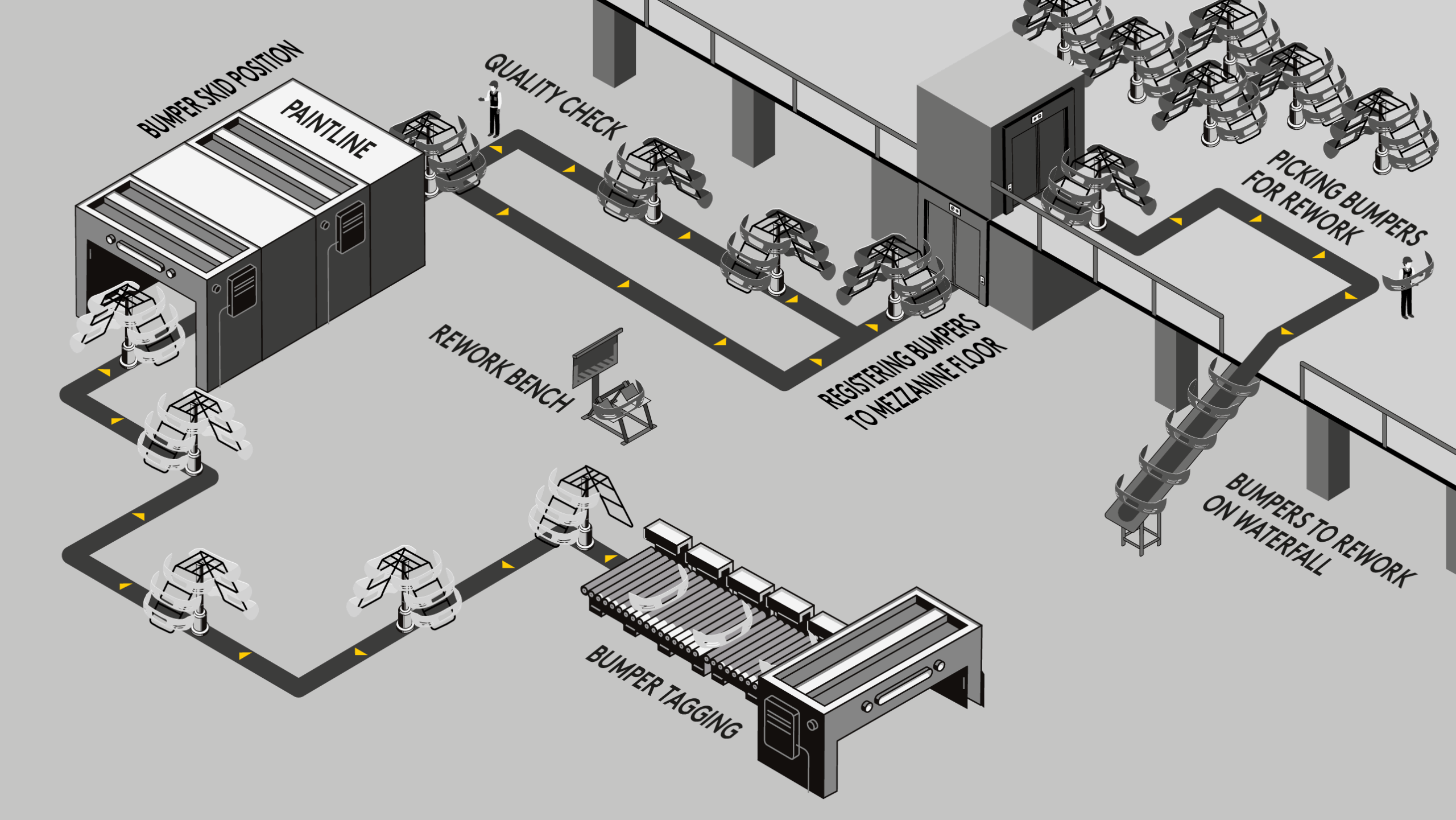

This picture depicts an example from a bumper manufacturer.

Bumper Tagging

At the end of production each item is RFID tagged and placed on the skid.

Bumper on Skid

Each item's position on the skid is registered before entering the paint line.

Quality Check

Upon exiting the paint line, items are inspected for quality and automatically routed to rework if necessary.

Rework Bench

The rework process for each affected item is registered through automatic data capture at the workbench.

Lift to Mezzanine Floor

The transition to mezzanine-level interim storage is logged in real time, with updated location data for each item.

Picking for Rework

Items requiring rework are registered using mobile devices and transferred down the waterfall path for further processing.

Waterfall

Items moving down the waterfall to rework are tracked and registered by the RFID system.

Bumper Tagging

At the end of production each item is RFID tagged and placed on the skid.

Bumper on Skid

Each item’s position on the skid is registered before entering the paint line.

Quality Check

Upon exiting the paint line, items are inspected for quality and automatically routed to rework if necessary.

Rework Bench

The rework process for each affected item is registered through automatic data capture at the workbench.

Lift to Mezzanine Floor

The transition to mezzanine-level interim storage is logged in real time, with updated location data for each item.

Picking for Rework

Items requiring rework are registered using mobile devices and transferred down the waterfall path for further processing.

Waterfall

Items moving down the waterfall to rework are tracked and registered by the RFID system.

Solution benefits

Accurate Process Step Tracking

Improved Quality Management

Real-time updates to Inventory & Status

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.