Asset Digitalization

Drive instant asset digitalization with RFID and RTLS technologies. All it takes is applying the right tag to any object.

Bridging the Physical and Digital Worlds with Correct Tag Selection

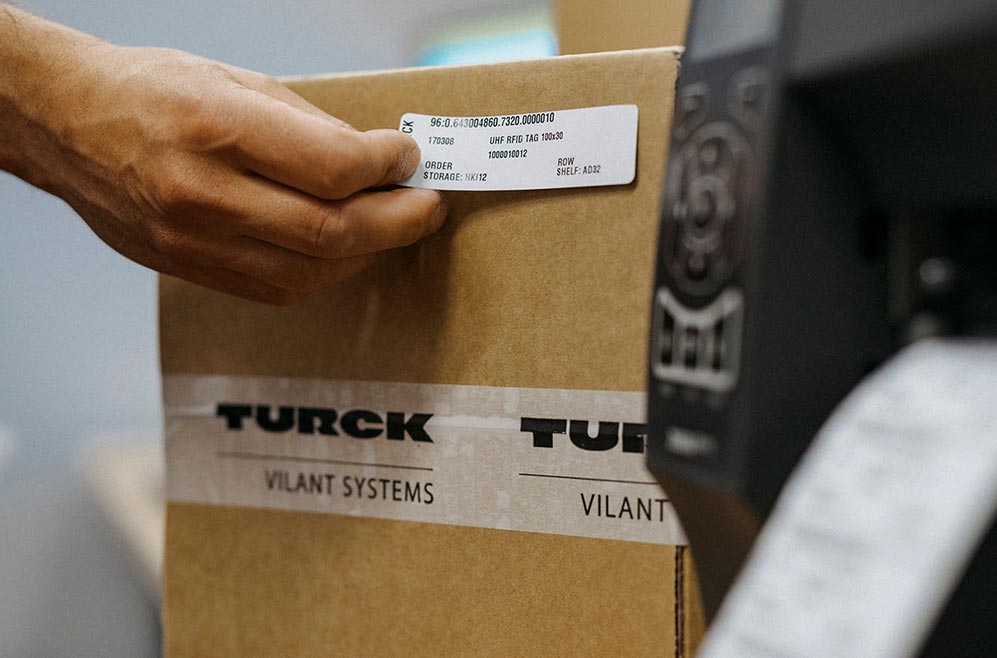

RFID technology delivers real-time visibility across materials, components, assets, and finished goods. Durable tags can stay with returnable assets, but item- and package-level applications typically rely on disposable, single-use labels. RFID and active tagging ensure visibility – We help you select a suitable tag for your items and determine whether you need passive UHF RFID tags or active RTLS tags.

Our RFID and RTLS Tagging Solutions

Visibility to materials, assets, and ready inventory is crucial for smooth customer service for our manufacturing, retail, and logistics customers. RFID and RTLS technologies help enhance visibility cost-effectively. Tags at the heart of tracking solutions often rotate with the asset but are typically of a single-use when applied on the item or packaging level. The key is selecting the correct type of tag for your needs.

As an industry expert and long-term integrator, Turck Vilant Systems has years of experience in RFID printing and tagging solutions. Before starting any project, we help customers define the tag most suitable for their trackable object, plan the tag application process, and, in the case of battery-assisted active tags, the tag change process.

The Difference between Active and Passive Tagging

There are different options to tag items that should be remotely identifiable. The most commonly used identification technology must still be barcodes. However, they cannot be mass-read but require line-of-sight and active participation on the operator’s side. RFID and RTLS tags need little or no action from operators and thus help automate the tracking of individual objects.

RFID tags are considered passive, as they need to be activated by an external antenna. RTLS (including BLE, UWB, GPS and similar) tags are considered active as they will report their position data independently without extra activation.

The table below compares the two approaches.

Passive Tagging

-

Needs Reader to Power them up

-

Care-free and Functional After Years of Use

-

Cost Effective

-

Support Mass Identification

-

Well-suited for Item-Level tagging even with Lower-Priced articles

-

Hard-tag versions Fit Well Returning Carriers

Active Tagging

-

Tags Have Integrated Radio

-

Technologies may include BLE, UWB, GPS, WiFi low energy

-

Tags come with Integrated Battery

-

More Costly than UHF RFID, but also More Exact in Localization

-

Fit Well Returning Carriers

-

Well-suited for Forklift Locationing and Combining to UHF RFID to Identify Materials on Fork

Turck Vilant Systems Services for Tag Selection

- Selecting between active or passive tracking technology

- Picking the perfect RFID tag inlay and casing or RTLS tag type

- RFID Label Design Service

- High-Quality Printing Support

- Data Integration between Systems

How we implement RFID and RTLS Tags

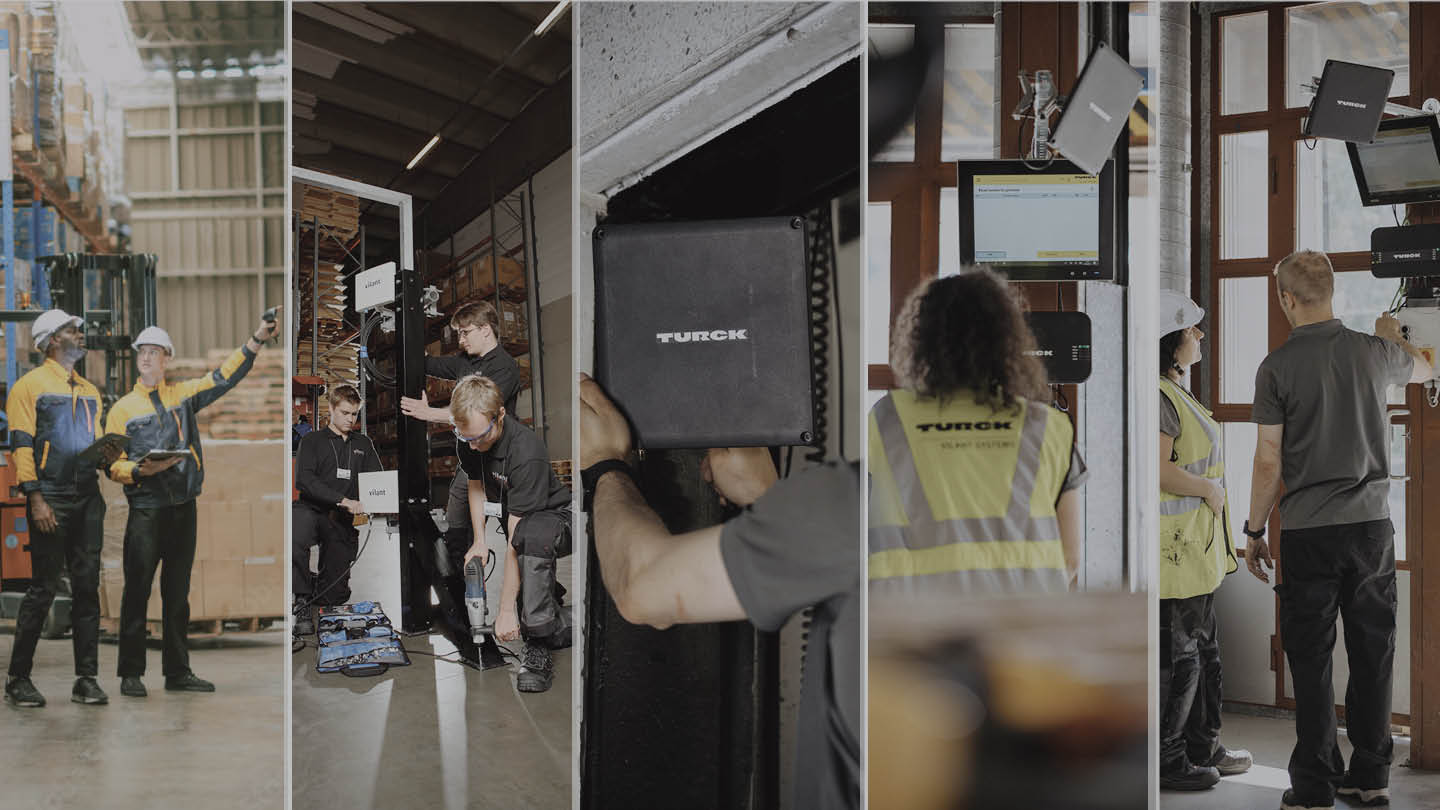

Recognizing that every business has unique RFID needs, our 5-step project model—from RFID Site Survey to Roll-out—is engineered for your success. We initially analyze the type of items requiring tags and the level of data collection desired. This foundational analysis then guides the development of a tailored project scope, detailing the necessary technologies and ideal tags.

Site Survey

Site Survey at the customer site allows our team to assess RFID suitability for those conditions.

Feasibility Tests

A proof of concept at customer premises is crucial for project planning and KPI definition. Our team brings the necessary equipment to thoroughly test the technology.

Pilot

To optimize business processes and data accuracy, a pilot is recommended for a few months.

This allows for testing not only the read point data accuracy but also the process flow for users, collecting their valuable feedback. A pilot can be scaled to fit specific needs, from a single dock door or production line to an entire site.

Roll-out & Production

Following a successful pilot, full-scale RFID implementation can commence. Support is provided throughout the process to define integration with all necessary business applications, optimize RFID read point functionality, and address staff training needs.

Support

Once operational, a 24/7 support agreement is available, ensuring service is readily accessible whenever the RFID system requires attention. As a standard, all customers are included in the 8/5 support program.

Site Survey

Site Survey at the customer site allows our team to assess RFID suitability for the customer organization.

Feasibility Tests

A proof of concept at customer premises is crucial for project planning and KPI definition. Our team brings the necessary equipment to thoroughly test the technology.

Pilot

To optimize business processes and data accuracy, a pilot is recommended for a few months. This allows for testing not only the read point data accuracy but also the process flow for users, collecting their valuable feedback.

A pilot can be scaled to fit specific needs, from a single dock door or production line to an entire site.

Roll-out & Production

Following a successful pilot, full-scale RFID implementation can commence. Support is provided throughout the process to define integration with all necessary business applications, optimize RFID read point functionality, and address staff training needs.

Turck Vilant Tag Selection and Design Services

Wide selection of inlays, tags and active tags in various frequencies ensuring worldwide support.

Ensures best tag for customer user case.

How to get started?

Our Experts are available to help you with RTLS & RFID implementation, planning, KPI setting, installation, tests, training and any other tasks you may have.

Read More

RFID Printing

High-Quality RFID Labels

Our RFID printing application ensures each tag is encoded and printed flawlessly when producing single-use RFID tags or labels.