RFID or RTLS for Enhanced Visibility

Logistics often suffers from a lack of systematic tracking for returnable transport items (RTIs) like pallets and crates. This leads to costly container shrinkage, shortages, extensive search times, and increased expenses from safety stocks. This white paper outlines the significant value of using Track & Trace systems to efficiently manage RTI pools across the entire production process chain, delivering enhanced visibility and control.

The Imperative for Real-Time RTI Control

Treating reusable transport items as disposable is economically unsound, tying up valuable capital and risking costly supply chain disruptions. Inefficient management, damage, or loss of RTIs lead to expensive procurement of additional containers, potentially causing production downtime, especially for Just-in-Time (JIT) or Just-in-Sequence (JIS) lines. Often, the exact number of containers in circulation remains unknown. RFID-based load carrier management addresses these challenges by enabling low-administration tracking, speeding processes, and preventing manual errors, ensuring RTIs are available precisely when and where needed.

“Simply put, it doesn’t make economic sense to invest in reusable transport items only to treat them as disposable ones.”

Why Passive UHF RFID is the Ideal Solution

While various identification technologies exist, Passive UHF RFID emerges as the ideal solution for comprehensive RTI tracking due to its superior advantages. Unlike traditional barcodes, RFID allows for fast, automated bulk reading without line-of-sight, even on challenging materials like metal or ESD plastic. Compared to more expensive active technologies or GPS, passive UHF offers optimal performance with the lowest tag cost, making it the standard for efficient RTI management.

How RFID Transforms RTI Management

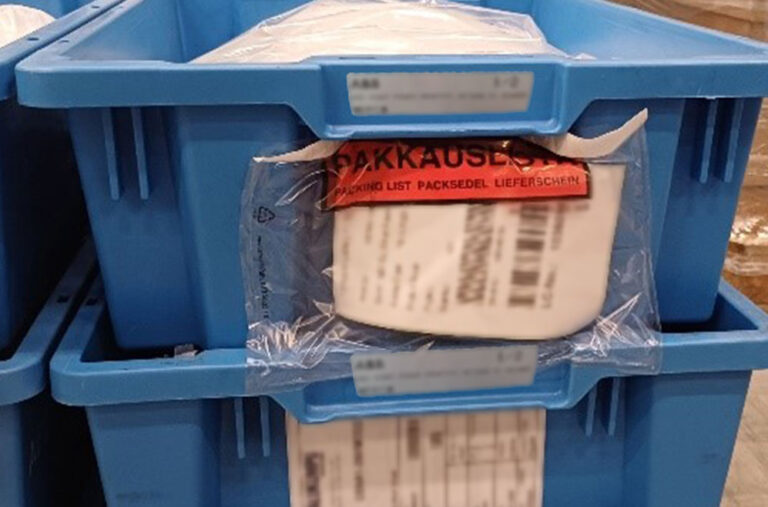

A state-of-the-art RFID solution for RTIs typically involves durable tags (often embedded or attached during production), specialized RFID read points (gates, forklifts, handhelds for diverse process steps), and central RFID server applications. These server applications handle data consolidation, system health, and seamless integration with existing business systems (ERP, WMS). This comprehensive architecture provides real-time inventory visibility, enables quality control, ensures accountability for RTI movements, and facilitates the “marriage” of RTIs with their contents for precise tracking.

Conclusion

RFID-based container management swiftly recoups its cost through enormous savings achieved by ensuring RTIs are always in the right place at the right time. By linking physical objects with IT data, RFID systems generate the transparency crucial for lean processes and resilient, digitized supply chains.

Download the full white paper to explore how RFID can revolutionize your RTI management, enhance efficiency, and reduce costs in your production logistics.

Download White Paper

Unlock expert insights into digitizing your sales and supply chain. Our team has put together this White Paper to give you insights and best practice tips.

You can also find the direct contact details of our Sales team here.