RFID enables paper core and paper roll tracking

RFID provides real-time supply-chain visibility for paper rolls and cores

A short introduction to RFID enabled paper roll and core tracking

The manual handling of paper roll and core inventory is time consuming and prone to error. RFID offers a cost effective method to identify individual paper rolls and cores remotely enabling automatized tracking of their movements and usage, which in turn leads to higher production efficiency.

Turck Vilant Systems is a world leader in pulp and paper tracking. Our RFID solutions keep a record of pulp and paper products around the globe on four continents. Specialized knowledge in pulp and paper manufacturing processes has helped us develop perfect products to support the needs of the industry.

Turck Vilant Systems RFID Solution for paper rolls and cores

-

-

-

-

- Gives a unique identity to each paper roll or core

- Follows cores on winder and during production process

- Keeps record of all warehouse transfers made with forklifts

- Ensures delivery accuracy by verifying correct products are loaded

- Logs all RFID events and documents the history of paper roll and core movements

- Tracks the consumption of paper during production process

-

-

-

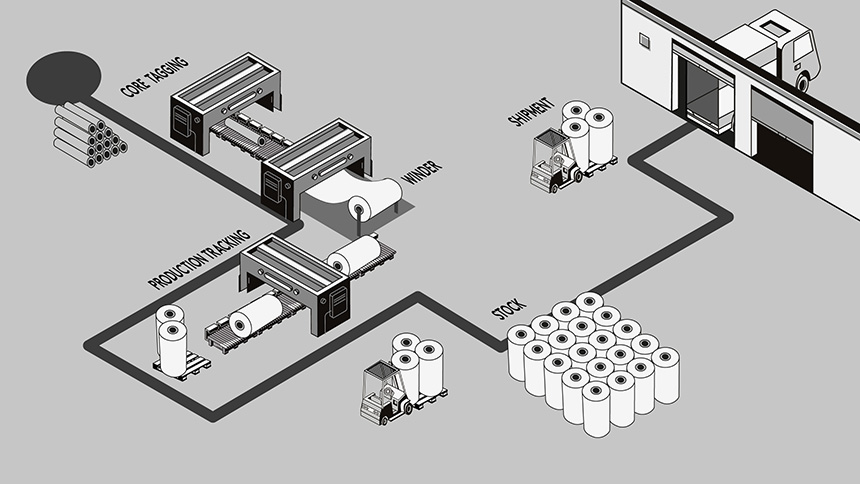

Core tagging

Individual cores are RFID tagged or when recycled in the factory, their data is updated

Winder

Each core is identified as it enters the winder. The RFID data is matched up with the data in the MES.

Benefits

Correct stock data

Loading control and reduction of shipment errors

Less manual work

Visibility on which cores are on the winder and ability to change their order easily

Ability to automate the paper roll route on production line

Reduction of manual errors

Streamlined FIFO operations

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.