RFID tracks chemicals all the way from production to customer

The tracking of chemical materials from supplier to production and all the way to end customers was never this straight-forward

A short introduction to how RFID Tracks Chemicals in big bags, barrels and IBCs

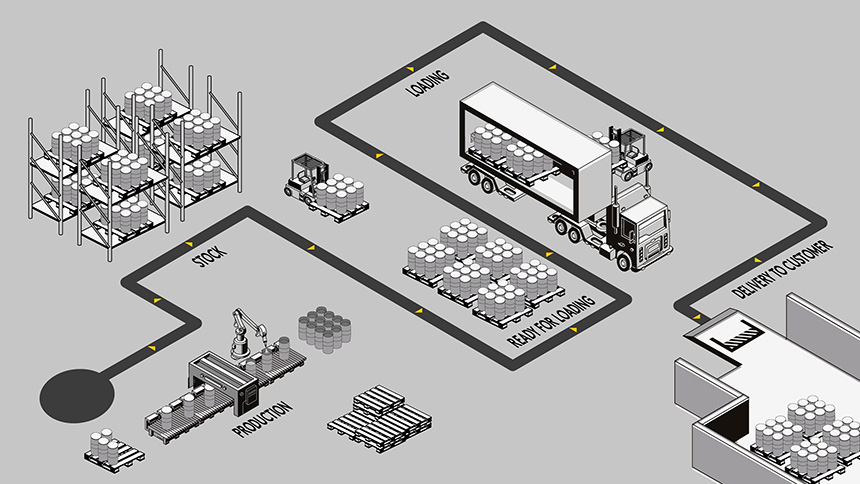

Chemical products such as liquid and powder are challenging to tell apart by nature. RFID helps give a unique and easily traceable identity to barrels, big bags, or IBCs (intermediate bulk containers). Hence picking, finding, loading, and tracking chemical matters speeds up. Once production fills a container with the finished product, it gets a unique identity in the form of an RFID tag. The container may have a readily applied RFID tag on it, or the tag can be applied in the final stage of production. The factory, warehouses, distribution centers, and partner (e.g., 3PL) facilities can be equipped with suitable RFID read points, which track the container and pull up any needed batch or production data related to the container. Using RFID to track chemicals packed in containers helps fulfill legal obligations, track warehouse movements, and remove manual errors through automation.

Fulfilling legal track and trace obligations often requires backward traceability. In practice, organizations must record any movements in the supply chain. Since different actors in the chemical supply chain have various facilities, Turck Vilant Systems has worked with customers to create the perfect combination of RFID read points to follow the chemical trail. Our customers can mix and match RFID for production lines, the usage of mobile devices, and RFID Gates, and in large warehouses, many use forklifts, payloaders, and tractors equipped with RFID readers.

Turck Vilant Systems RFID-based Chemical Tracking Solution

-

-

-

-

- Gives a unique identity to each container and matches production batch-related data to it

- Keeps record of all warehouse transfers made with payloaders, forklifts or tractors

- Ensures delivery accuracy by verifying correct products are loaded

- Logs all RFID events and documents the history of movements for each individual product

- Visualizes product availability per location

-

-

-

Benefits

Ready solution for liquids, powders and specialty chemicals

Realtime storage information

Easy identification of individual containers and production data related

No more manual errors

Streamlined FIFO operations

Fulfills legal obligations

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.