Material Tracking

A short introduction to material tracking with RFID

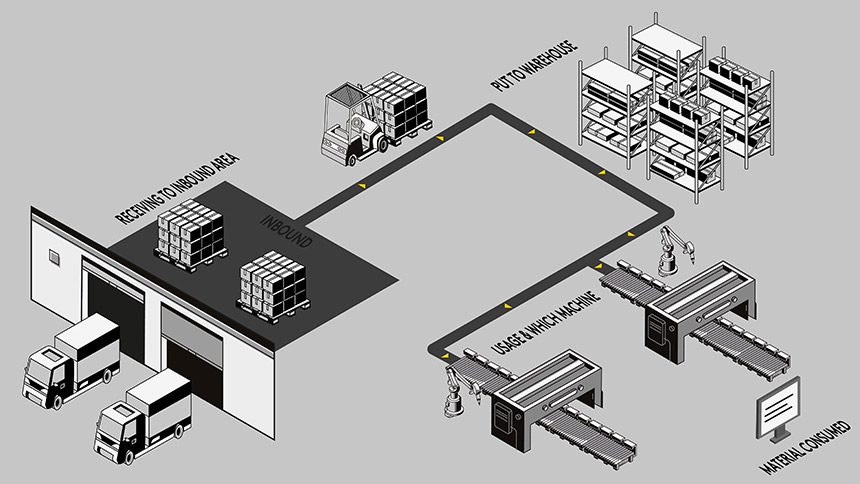

Material management is a crucial part of any manufacturing operation. Most have hundreds or even thousands of suppliers for a variety of raw materials and components and an efficient production schedule requires good planning and on-time visibility for deliveries and material stock. An investment in RFID offers manufacturing companies a fast material receiving process, data-based ordering, and an ability to respond fast to changes in demand. Furthermore, the data collected from various RFID read points can be used for quality assurance as well as later for after sales or product withdrawal matters.

Receiving

Material is received from suppliers through RFID gates that automatically receive the goods to backend system

Shelving

Material is moved to inbound warehouse through RFID gates or with forklifts equipped with RFID readers. Stock transfer to new location is automatically updated to WMS. With forklift RFID system, location can be automatically updated to exact shelf position

Benefits

Faster material receiving

On-time material inventory

0 material errors when feeding material to machine

Easy backwards traceability of production batches

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.