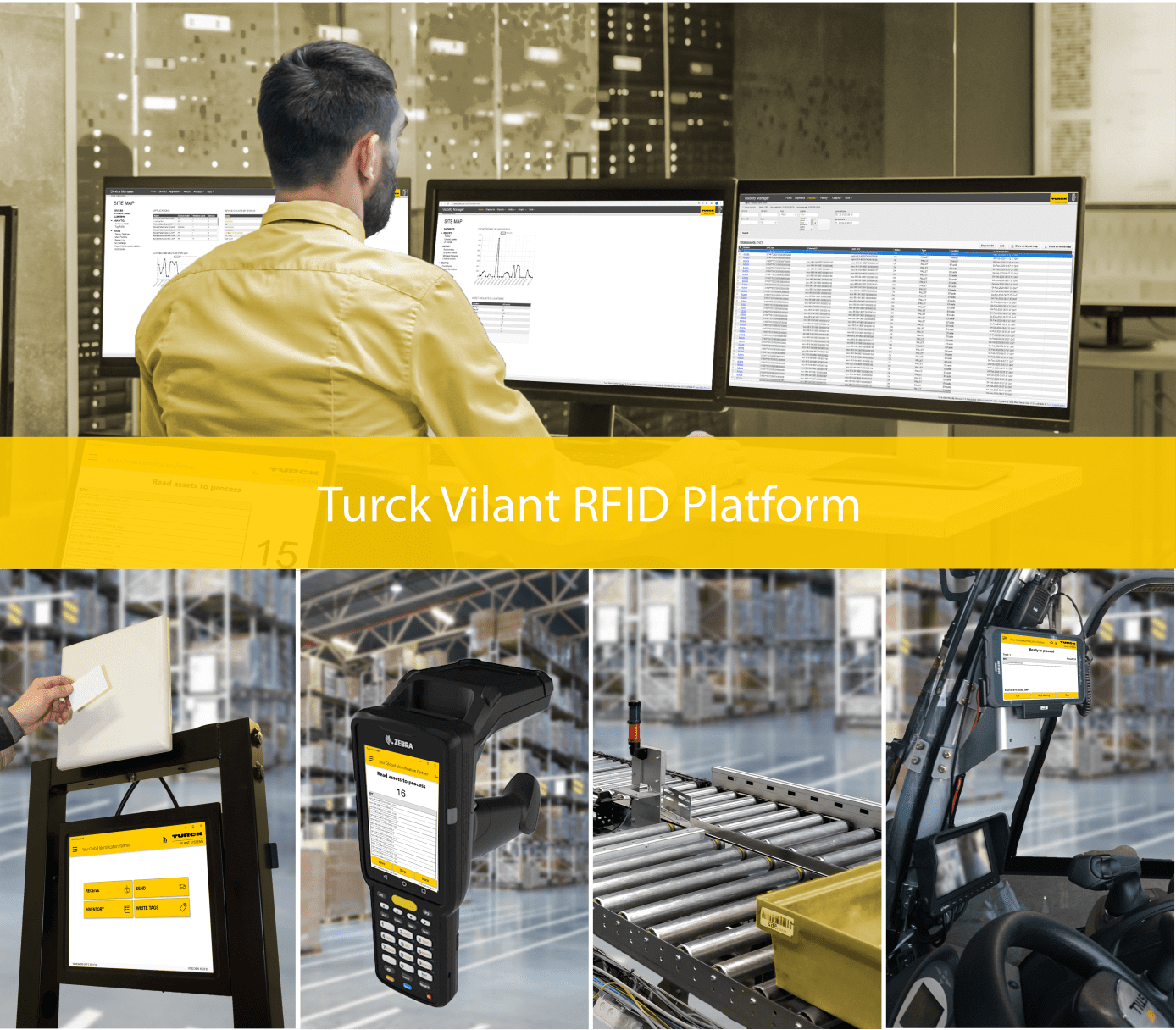

RFID Applications

RFID systems revolutionise the way businesses track goods and manage their inventory. Our comprehensive RFID platform serves the need for traceability troughout your entire supply chain ensuring material availability, inventory visibility and delivery accuracy.

Comprehensive RFID Application toolkit to serve a digital Supply Chain

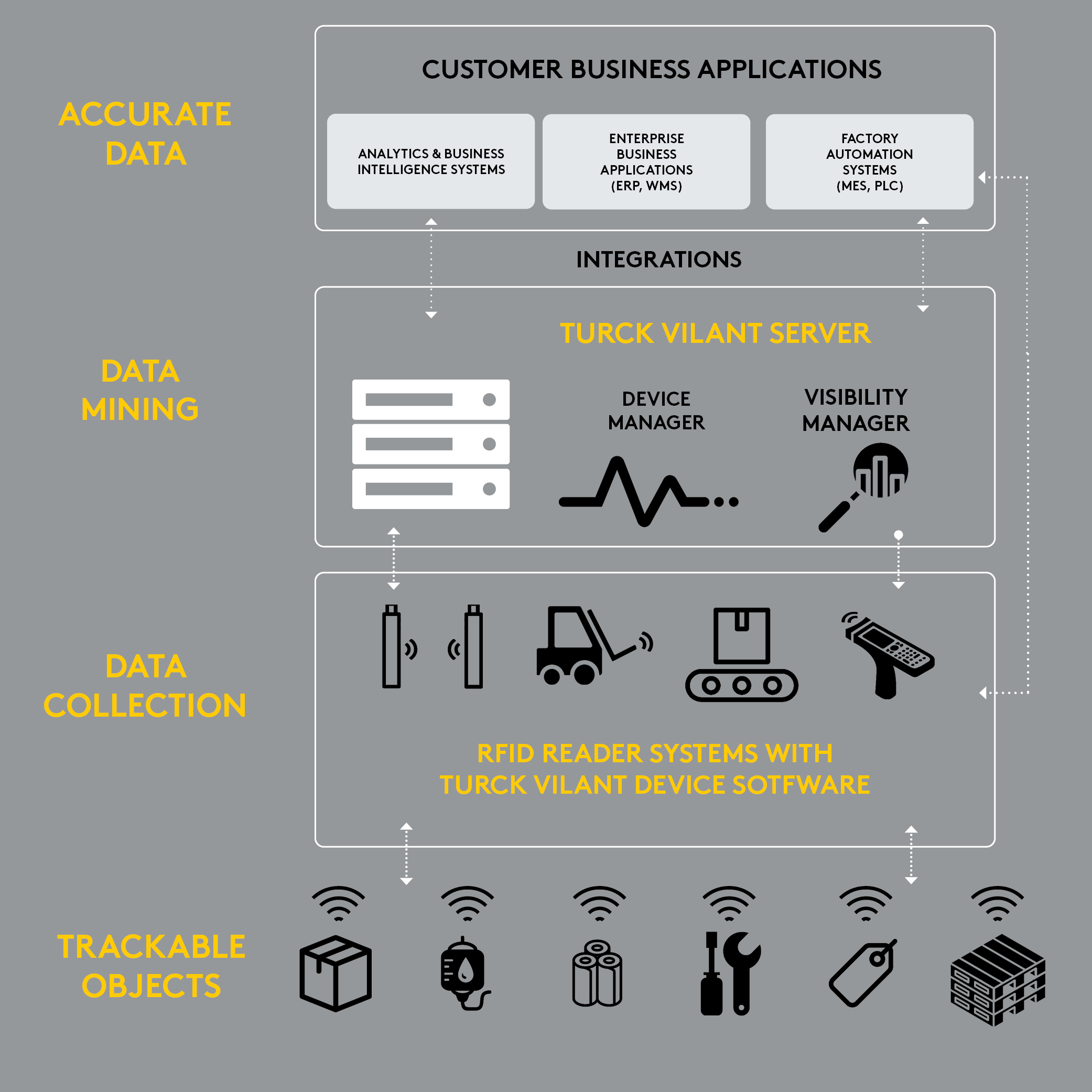

Almost any object can be equipped with a UHF RFID tag and thus it is identifiable reliably, and from a distance. Once RFID tagged, the object leaves a digital trace that business processes use for supply chain automation such as automatic registering of inbound or outbound goods, monitoring work progress or material consumption.

The Turck Vilant Systems RFID applications are designed following the industry standards ratified by GS1, and has ready-to-use components for all typical RFID use cases.

The Turck Vilant Server applications collect, consolidate, control and mine data from different RFID read points as well as control and monitor the health of individual readers and read points.

Furthermore the collected data can easily be actioned upon, either directly on the read point level (for example alerting of mistakes such as delivery errors) or later based on reports on the server (for example generating an order for raw materials when system shows low inventory levels).

Our RFID Platform consists of

RFID Server

Turck Vilant server applications (cloud or local) for Data Mining and System Health and Maintenance including an integration layer with support to most common ERP and WMS systems

In-house developed RFID middleware for different read points with 30+ ready applications supporting intralogistics processes in varied industries including warehousing, automotive, chemical, pulp & paper and transport.

Key features

- Integration to most common ERP, WMS and MES systems

- RFID middleware to be used on gates, forklifts, conveyor belts, mobile devices and commanding printers and applicators

- Support of most common industrial use cases such as inventory management, goods receipt tracking, material commissioning, picking and shipping

Read more about our RFID Products

Smart Cabinet empowered by RFID

RFID-enabled lockers supporting the sharing of tools, protective equipment or stock

Read moreMobile RFID

Discover what is in stock, execute quality checks and locate items with a mobile device that serves users exactly where they work.

Read moreRFID printing

The key to working RFID systems is the tags, often encoded and generated with industrial printers.

Read moreQuestions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project. Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences. You can also find the direct contact details of our Sales team here.